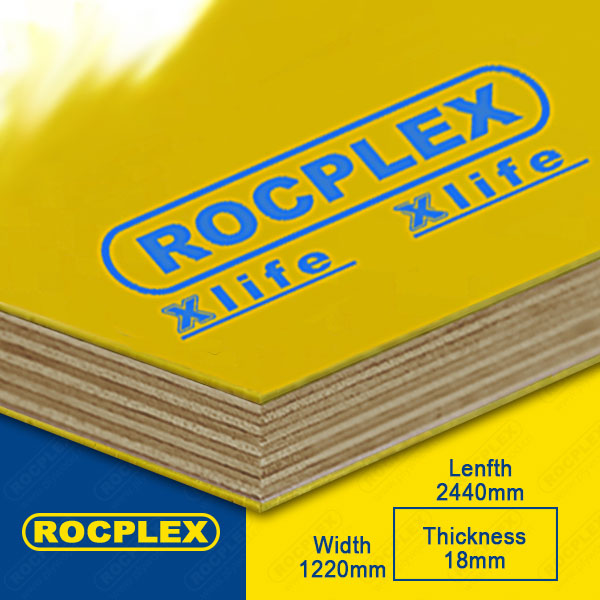

Cheapest Factory Concrete Path Forms - 18mm ROCPLEX Xlife Formply Plywood Sheet – ROC

Cheapest Factory Concrete Path Forms - 18mm ROCPLEX Xlife Formply Plywood Sheet – ROC Detail:

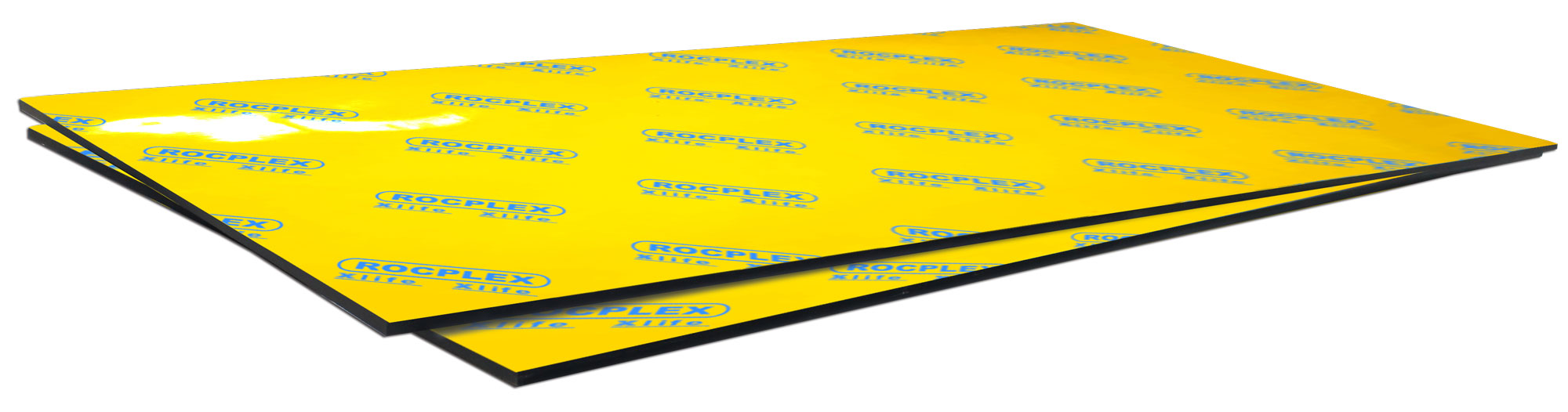

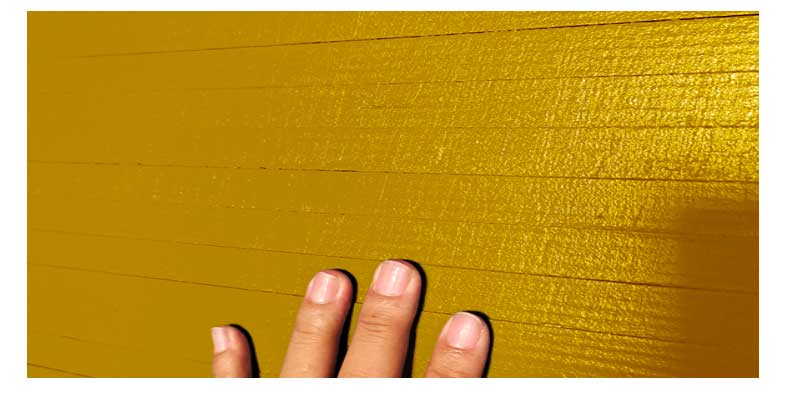

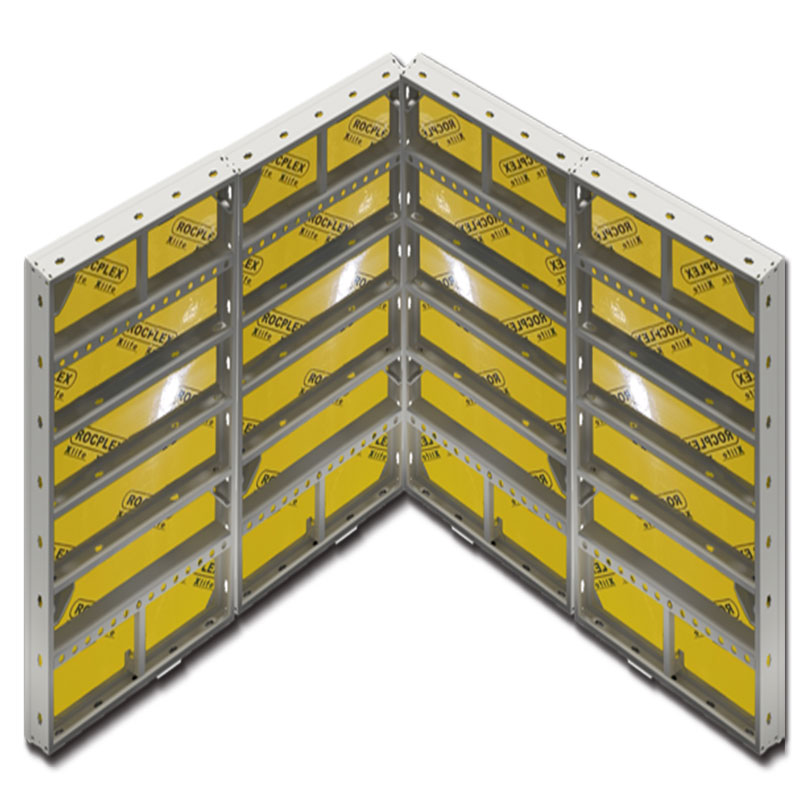

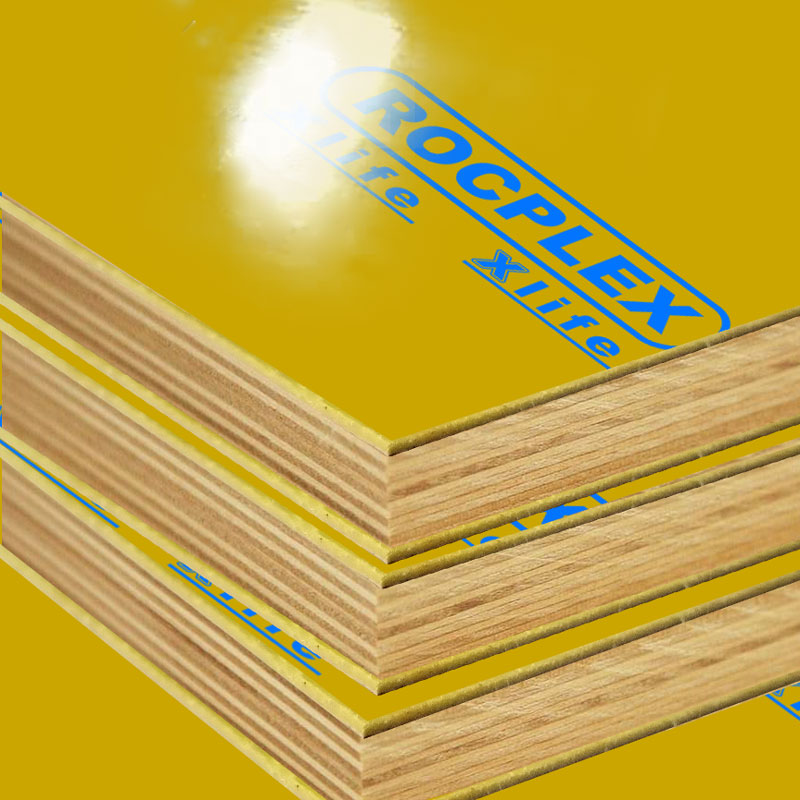

ROCPLEX Xlife formwork plywood sheet is high-grade plastic /wood composite sheet with hard-wearing plastic coating for a significantly longer lifespan and uniform concrete faces over a long time of service.

Manufactured From High-grade Birch Veneers Bonded Together With Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The oblique jiont and hot-melt splicing technology are used to avoid every possible gap.

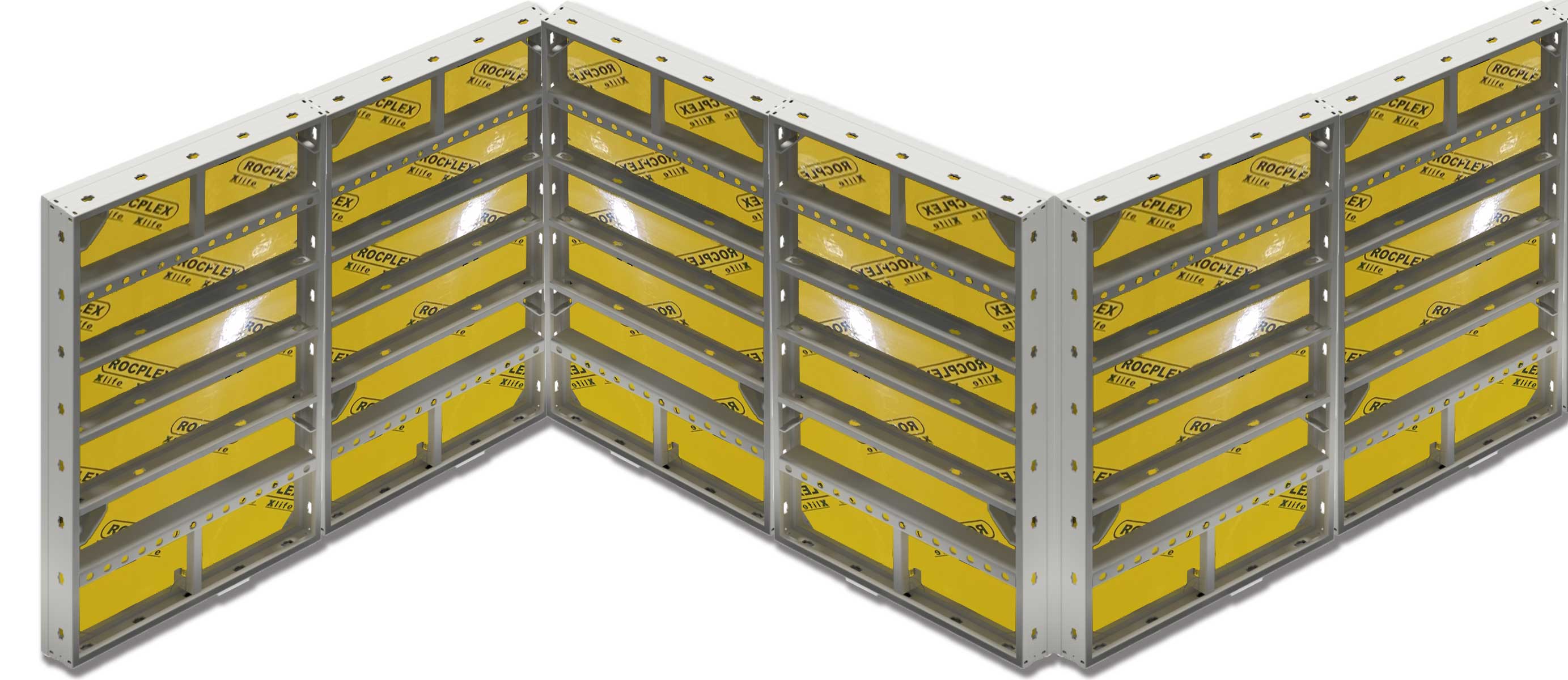

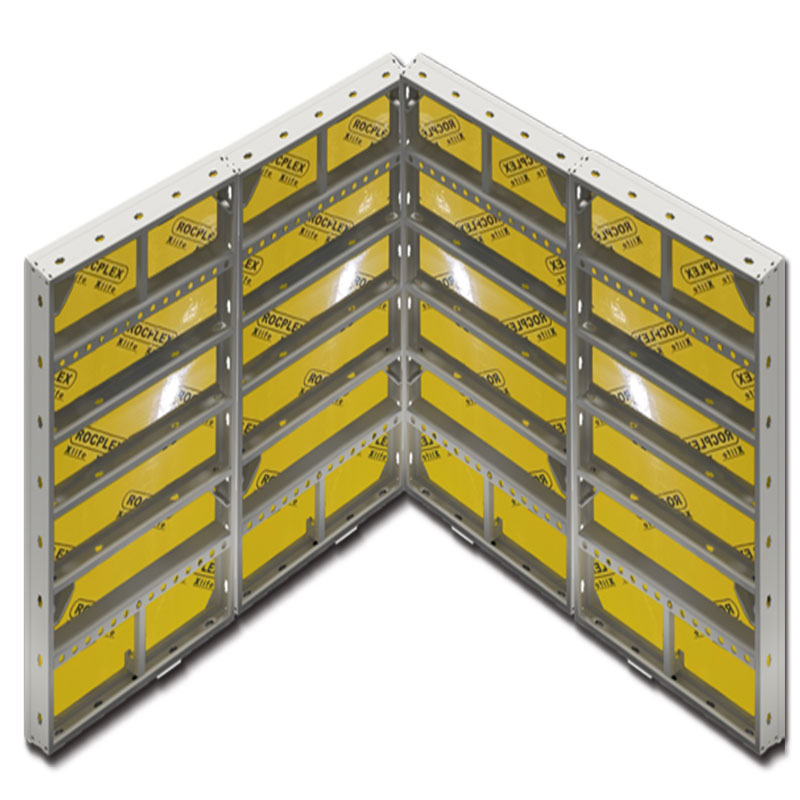

ROCPLEX Xlife formply plywood for strong, stable, concrete formwork

ROCPLEX Organic Toughened Plastic Facing Does Not Absorb Water.

It Does Not Swell Or Shrink. The Robust, Smooth Surface Guarantees First-class Concrete Quality Even After Many Uses.

Given Optimum Conditions Of Use And Correct Handling, Max Up To 350 Use Cycles (guide Value) In Frame Formwork Can Be Achieved.

Due To Their Durability, The Rocplex Xlife Plywood Sheet Are A Good For Formwork Applications.

Manufactured From High-grade Birch Veneers Bonded Together With Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The Oblique Jiont And Hot-melt Splicing Technology Are Used To Avoid Every Possible Gap.

To Ensure Excellent Hardness And Stability.

Super E0 Waterproof Adhesive. If Put In Boiling Water For 72 Hours, It Is Still Glue-sticking And Non Deformed.

The Edges 3 Times Sealed With Waterproof Paint In The Factory For Minimise Moisture Penetration.

|

1 |

Face and Back |

1.0mm plastic double side |

|

2 |

Grade |

AA garde |

|

3 |

Core Materials |

Full Birch Core |

|

4 |

Glue Choose |

Waterproof Super E0 Glue |

|

5 |

Thickness |

6-28mm(normal thickness:12mm, 15mm, 18mm, 21mm) |

|

6 |

Specification |

1220mmX2440mm,1250mmX2500mm,1200mmX2400mm ,1200mmX1800mm |

|

7 |

Moisture Content |

8-14% |

|

8 |

Density |

730-780 kg/ m3 |

|

9 |

Cycle Life |

More than 350 times |

If put in boiling water for 72 hours, it is still glue-sticking and non-deformed.

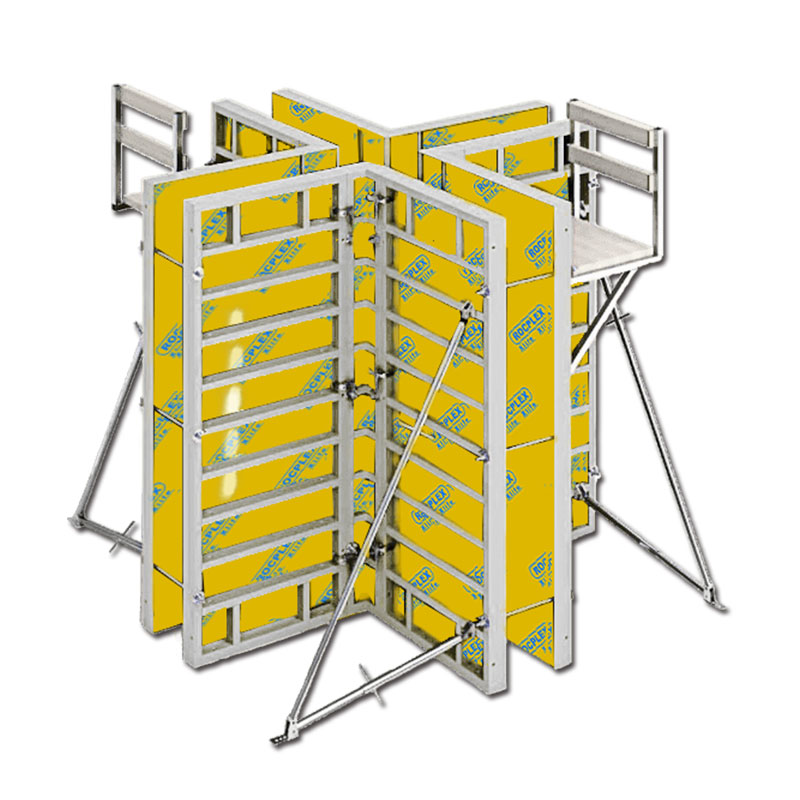

Physical mood is better than iron moulds and can satisfy the requirements of constructing mould,the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing.

If used abide by the illustrations strictly, it can be reused more than 350 times.

Reducing the cost greatly and avoiding the disadvantages from ( rustily and erosive of iron mould).

Solves the problems of leaking and rough surface during constructing process.

Particularly suitable for watering concrete project ,can make the concrete surface smoonth and flat.

|

ROCPLEX Xlife Formwork Plywood Save cost |

||

|

Be special for phenolic glue and film |

The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

||

|

Be special for adhesive |

||

|

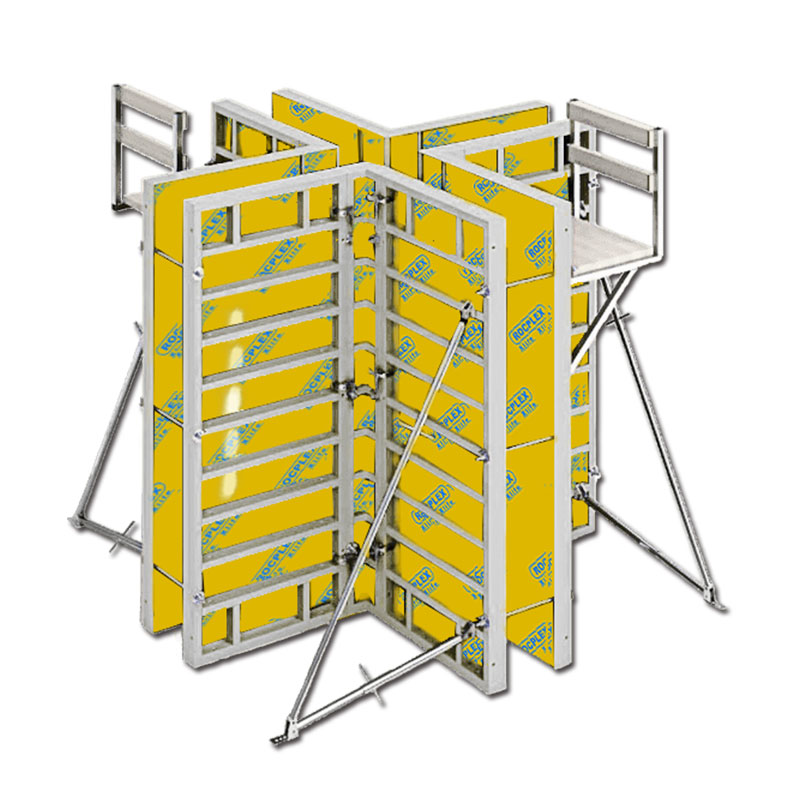

ROCPLEX Xlife Formwork Plywood Shorten duration |

||

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

||

|

Be easy to incise and blend |

||

|

ROCPLEX Xlife Formwork Plywood the high quality of casting |

||

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

||

|

The edges are polished carefully |

||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

|

|

|

Product detail pictures:

Related Product Guide:

ROCPLEX matine plywood

Questions and answers encountered in the use of plywood plates

Our staff are usually in the spirit of "continuous improvement and excellence", and while using the top-quality high-quality items, favorable value and superior after-sales services, we try to acquire each and every customer's belief for Cheapest Factory Concrete Path Forms - 18mm ROCPLEX Xlife Formply Plywood Sheet – ROC , The product will supply to all over the world, such as: France, Montreal, Paraguay, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our goods. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you personally always.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!