F17 Formply China wholesale Hot Selling Formply F17 Structural Plywood for Australia Market

We regularly execute our spirit of ''Innovation bringing development, Highly-quality making certain subsistence, Management advertising and marketing profit, Credit score attracting buyers for F17 Formply China wholesale Hot Selling Formply F17 Structural Plywood for Australia Market, With all the everlasting goal of "continuous high quality improvement, customer satisfaction", we are sure that our product or service excellent is secure and trustworthy and our merchandise are best-selling in the home and abroad.

We regularly execute our spirit of ''Innovation bringing development, Highly-quality making certain subsistence, Management advertising and marketing profit, Credit score attracting buyers for F17 Formply China wholesale Hot Selling Formply F17 Structural Plywood for Australia Market, With all the everlasting goal of "continuous high quality improvement, customer satisfaction", we are sure that our product or service excellent is secure and trustworthy and our merchandise are best-selling in the home and abroad.

We regularly execute our spirit of ''Innovation bringing development, Highly-quality making certain subsistence, Management advertising and marketing profit, Credit score attracting buyers for China F17 Formply and 4 X 8 FT., F17 formply, Formply F17, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

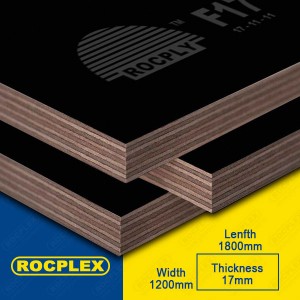

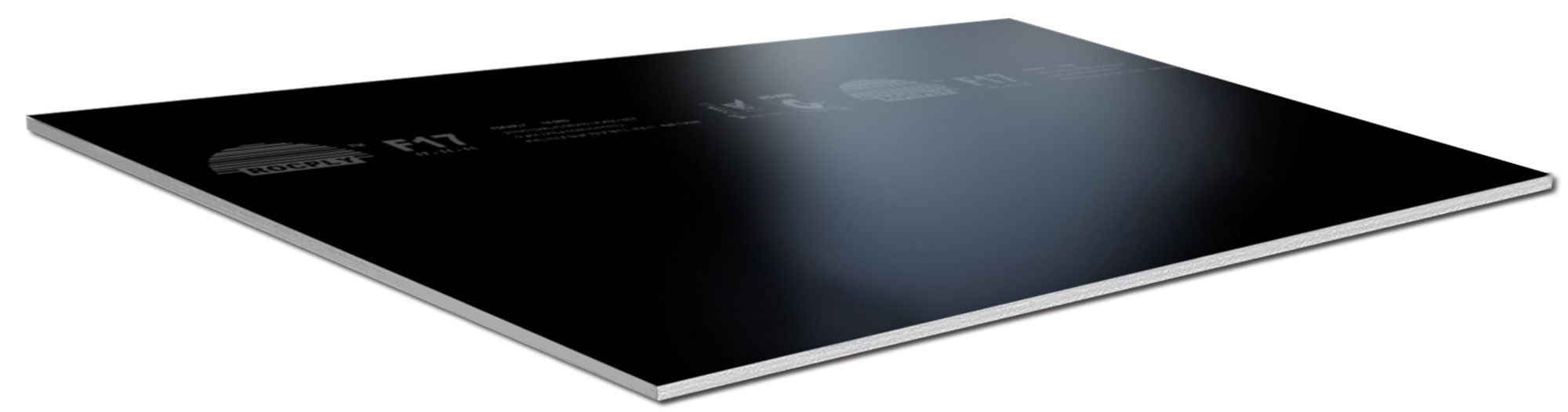

ROCPLY TM F17 Formply is plywood made with a high-density overlay (HDO) of Phenolic resin infused paper bond to give you an amazing off form finish and it’s structural integrity allows multiple reuses across the Concrete, Building and Construction Industries.

ROCPLY F17 Formply for strong, stable, concrete formwork

Manufactured From High-grade Full Hardwood Veneers Bonded Together With Custom Made Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The oblique jiont and hot-melt splicing technology are used to avoid every possible gap.

ROCPLY Formply is a high quality formwork plywood developed and engineered specifically for the Australian market.

With a three tier quality control program comprising;

AA detailed ‘Manufacturing Specification’ adhered to by trained staff;

Regular, detailed and recorded in house testing on key quality requirements and independent grading,

Testing and certification carried out by Certemark Iternational (CMI) and DNV.

ROCPLY Formply provides assurance of quality and consistency.

All veneer in the manufacture is certified Forest Stewardship Council (FSC) from sustainable forests.

ROCPLY formply plywood for strong, stable, concrete formwork

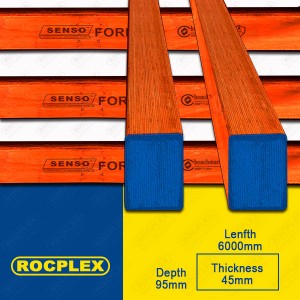

| Stress Grade | Sheet Size (mm) | Thicknesses (mm) | Weight (kg/sheet) | Parallel to face grain | Perpendicular to face grain | CoreMaterials | PackingUnit(sheets) | ||

| Momentof inertia | Sectionmodulus | Momentof inertia | Sectionmodulus | ||||||

| I(mm4/mm) | Z(mm3/mm) | I(mm4/mm) | Z(mm3/mm) | ||||||

| F17 SENSO | 1800×1200 | 12, 17, 19 & 25 | 24 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

| F17 SNESO | 2400×1200 | 12, 17, 19 & 25 | 32 | 240.0 | 27.6 | 178.0 | 22.9 | Full hardwood | 40 / 43 |

ROCPLY Special Custom HDO Film Facing Does Not Absorb Water.

And It Does Not Swell Or Shrink.

The Robust, Smooth Surface Guarantees First-class Concrete Quality Even After Many Uses.

Manufactured From High-grade Full hardwood Veneers Bonded Together With Super E0 Waterproof Adhesive, Which Has Superior Bond Strength.

The Oblique Jiont And Hot-melt Splicing Technology Are Used To Avoid Every Possible Gap.

To Ensure Excellent Hardness And Stability.

Super E0 Waterproof Adhesive. If Put In Boiling Water For 72 Hours, It Is Still Glue-sticking And Non Deformed.

The Edges 4 Times Sealed With Waterproof Paint In The Factory For Minimise Moisture Penetration.

|

1 |

Face and Back |

ROCPLY Special Custom Film |

|

2 |

Grade |

AA garde |

|

3 |

Core Materials |

Full Hardwood Core |

|

4 |

Glue Choose |

A bond Waterproof Super E0 Glue |

|

5 |

Thickness |

6-28mm(normal thickness:12mm, 15mm, 17mm, 25mm) |

|

6 |

Specification |

1800mmX1200mm, 2400mmX1200mm 1800mmX600mm , 2400mmX600mm |

|

7 |

Moisture Content |

8-14% |

|

8 |

Density |

730-780 kg/ m3 |

| ROCPLY Fomply Save cost | ||

| Be special for phenolic glue and film | The formply can be disassembled and used repeatedly for both faces,saving 25% of the cost. | |

| Optimization for the special grade of core | ||

| Be special for adhesive | ||

| ROCPLY Fomply Shorten duration | ||

| Excellent effect of demoulding | Shorten 30% of the duration. | |

| Avoid the reconstruction of the wall | ||

| Be easy to incise and blend | ||

| ROCPLY Formply The high quality of casting | ||

| The flat and smooth faces | The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. | |

| The structure of waterproof and breathability | ||

| The edges are polished carefully | ||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

10-12 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

20-27 pallets |

43 CBM |

25500KGS |

26000KGS |

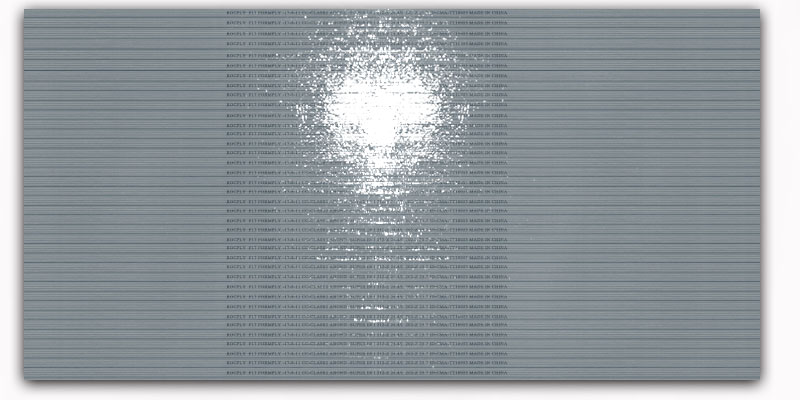

ROCPLY F17 Formply is a certified high quality laminated plywood for construction. Its core part is made of all hardwood veneers and bonded together with A-Bond adhesive. The surface is covered with high-density black waterproof film specially made by ROCPLY and hot-pressed.

ROCPLY adheres to the concept that innovation is the basis of development and high quality of life. Strictly control the quality of ROCPLY F17 Formply from management, lower the price of Formply F17 from innovation, serve F17 Formply China wholesale Hot Selling Formply F17 Structural Plywood for Australia Market buyer with sincerity and enthusiasm, and take "continuous high quality improvement, customer satisfaction" as the everlasting goal, from the feedback of many customers and thousands of tests conducted by our R&D team in China, we can confirm that the products or services of ROCPLY Formply are safe and reliable.

Wholesale F17 Formply, Formply F17, China F17 Formply and 4 X 8 FT. made in China. ROCPLY is a rugged, high-level building project template that is effectively promoted worldwide, especially in Australia and New Zealand. Strong and durable, waterproof and climate resistant, this is a must-have indicator of ROCPLY F17 Formply, I believe you will also admire the high quality of Formply when you use it. Under the guidance of the principle of "caution, efficiency, unity and innovation", ROCPLY strives to develop, improve the practicability of products, reduce the cost of products, and expand the export scale. We believe that in the coming years, ROCPLY F17 Formply will continue to make progress and provide you with better service at higher quality and price.

The ROCPLY F17 Formply base plate has been sanded twice and the surface is very flat. The specially customized waterproof film provides a smooth surface. Four times of waterproof edge sealing make the edges of the entire plywood smooth and effective waterproof. All these factors protect the whole hardwood core of ROCPLY F17 Formply, provide a solid and durable foundation factor for building formwork, and directly improve the quality of concrete pouring to a new level. This is also the fundamental reason why ROCPLY F17 Formply is so excellent.

ROCPLY F17 Formply, also known as Formply F17

General dimensions: 1800mm x 1200mm, 2400mm x 1200mm

Conventional thickness: 17mm

Stress grade: F17

Surface finish: Class 2 off-form finish on the first pour when used in connection with good site and formwork practices and AS 3610

Glue type: A-Bond phenolic resin adhesive, E0

Executive standards: AS 6669 – 2007, AS 6669 – 2016 – plywood – formwork