Manufacturing Companies for Premade Concrete Forms - Film Faced Plywood – ROC

Manufacturing Companies for Premade Concrete Forms - Film Faced Plywood – ROC Detail:

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

7.5 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

690 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.68 Min: 0.81 |

Check out |

|

Damage Rate |

% |

85% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6997 |

Check out |

|

Lateral |

6090 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

59 |

Check out |

|

|

Lateral |

43.77 |

Check out |

||||

|

6 |

Cycle Life |

About 15-25 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

605 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.59 Min: 0.79 |

Check out |

|

Damage Rate |

% |

82% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

6030 |

Check out |

|

Lateral |

5450 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

57.33 |

Check out |

|

|

Lateral |

44.79 |

Check out |

||||

|

6 |

Cycle Life |

About 12-20 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

Sr NO. |

Property |

Unit |

Test Method |

Value Of Test |

Result |

|

|

1 |

Moisture Content |

% |

EN 322 |

8.4 |

Check out |

|

|

2 |

Density |

kg/m3 |

EN 323 |

550 |

Check out |

|

|

3 |

Bonding Qality |

Bonding Qality |

Mpa |

EN 314 |

Max: 1.40 Min: 0.70 |

Check out |

|

Damage Rate |

% |

74% |

Check out |

|||

|

4 |

Bending Moudulus of Elasticity |

Longitudinal |

Mpa |

EN 310 |

5215 |

Check out |

|

Lateral |

4796 |

Check out |

||||

|

5 |

Longitudinal |

Mpa |

Mpa |

53.55 |

Check out |

|

|

Lateral |

43.68 |

Check out |

||||

|

6 |

Cycle Life |

About 9-15 Repeated Using Times Acoording To Projects By Formwork Application |

||||

|

ROCPLEX Film faced plywood Save cost |

||

|

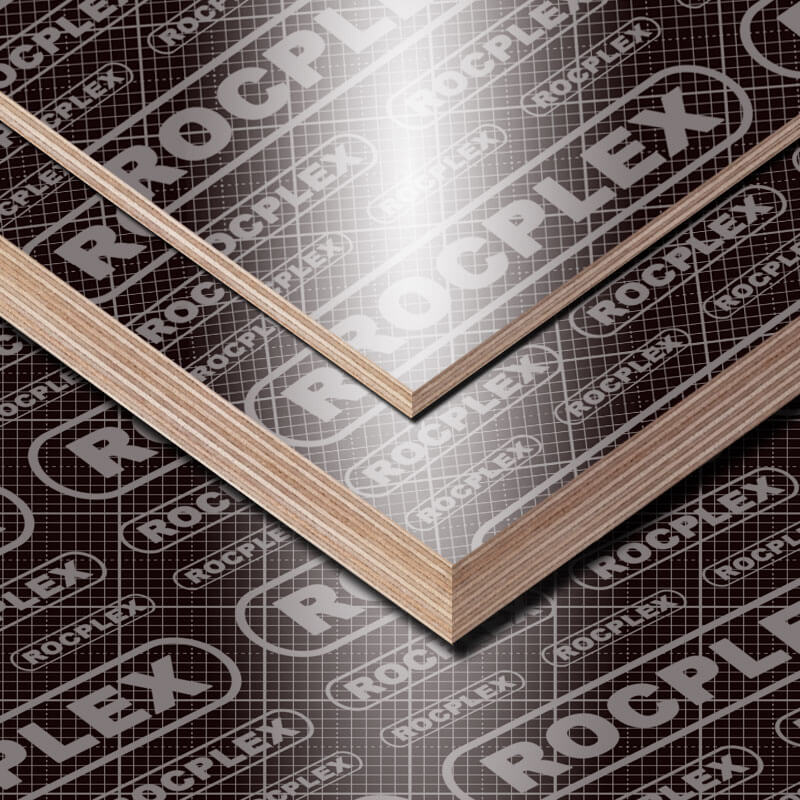

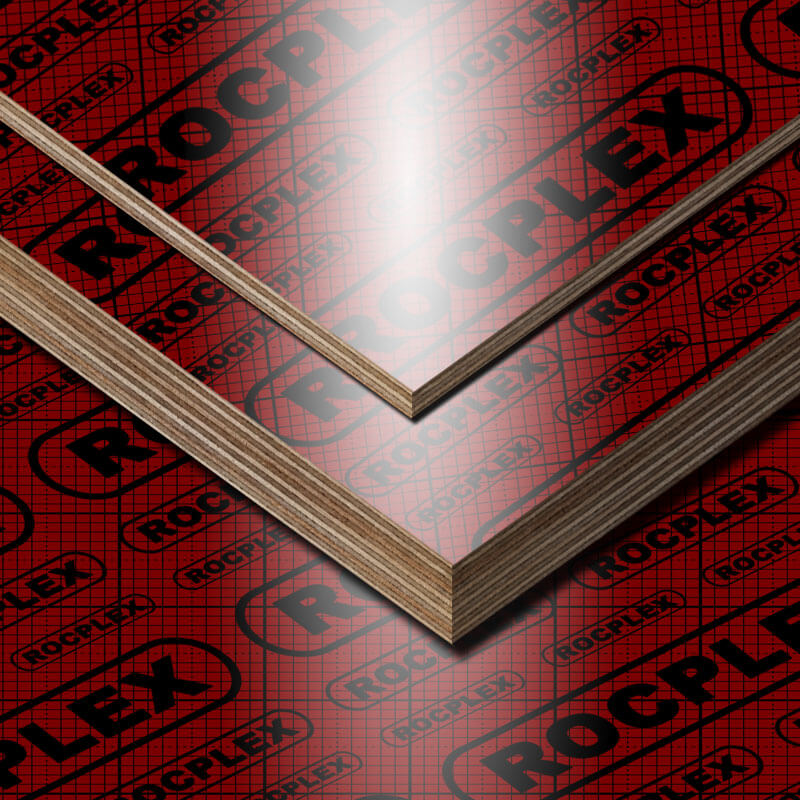

Be special for phenolic glue and film |

The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

||

|

Be special for adhesive |

||

|

ROCPLEX Film faced plywood Shorten duration |

||

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

||

|

Be easy to incise and blend |

||

|

ROCPLEX Film faced plywood the high quality of casting |

||

|

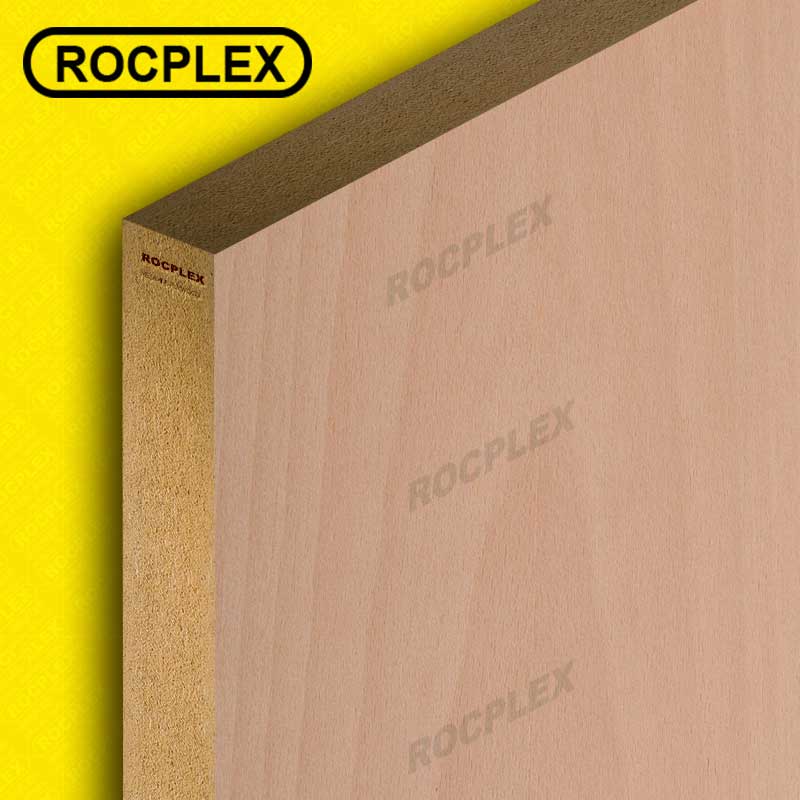

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

||

|

The edges are polished carefully |

||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

Meanwhile we also can supply you the formwork systerm accessories, commercial plywood , film faced plywood etc.

We specially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding chinese film faced plywood.

Product detail pictures:

Related Product Guide:

Questions and answers encountered in the use of plywood plates

China’s plywood production and import and export analysis in 2020: production is mainly wood plywood

We stay with the basic principle of "quality initially, services first, steady improvement and innovation to fulfill the customers" for your management and "zero defect, zero complaints" as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for Manufacturing Companies for Premade Concrete Forms - Film Faced Plywood – ROC , The product will supply to all over the world, such as: Oslo, Venezuela, UK, Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!