New Fashion Design for Ply Cost - Poplar Plywood 1220mmx2440mm 2.7-21mm – ROC

New Fashion Design for Ply Cost - Poplar Plywood 1220mmx2440mm 2.7-21mm – ROC Detail:

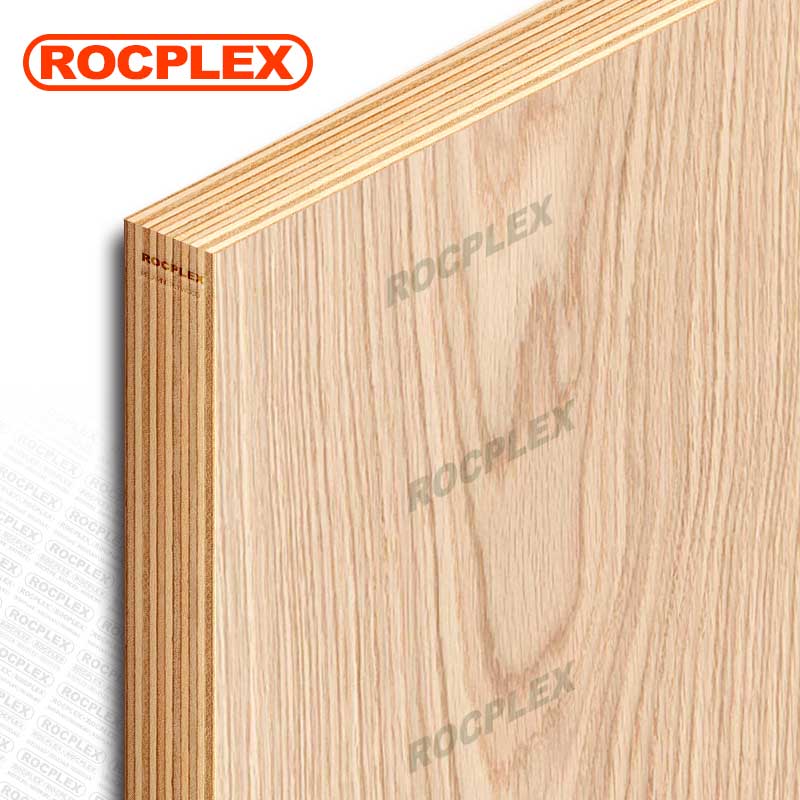

ROCPLEX poplar plywood is typically a high-quality product coming in 4′ x 8′ two-sided marine grade panels in thicknesses ranging from ⅛” to 1″. ROCPLEX poplar plywood made from natural poplar veneer are usually not pressure treated. The core can be made from pine, poplar, or hardwood to give it added strength.

poplar plywood is commonly used for building furniture or on kitchen cabinets because of its lustrous appearance.

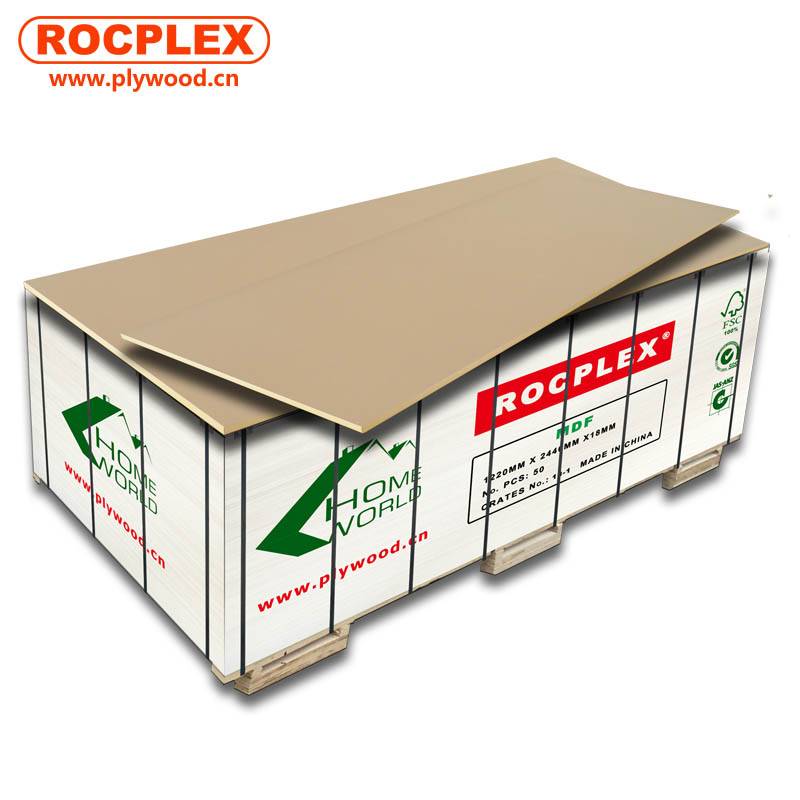

ROCPLEX poplar plywood with 2.7mm,3.6mm, 4mm, 5.2mm, 6mm,9mm, 12mm, 18mm,21mm normal thickness for choose.

ROCPLEX poplar plywood is a sheet material manufactured from thin layers or “plies” of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which includes medium-density fibreboard (MDF) and particle board (chipboard).

Testing and certification carried out by Certemark Iternational (CMI) and DNV.

ROCPLEX poplar plywood provides assurance of quality and consistency.

All veneer in the manufacture is certified Forest Stewardship Council (FSC) from sustainable forests.

|

Nomal Thickness |

Sheet Size (mm) |

Grade |

Density (kg/cbm) |

|

|

|

Glue |

Thickness tolerance |

Packing Unit (sheets) |

|

Face and back |

Core Materials |

Moisture |

|||||||

|

|

|

|

|||||||

|

1/8inch (2.7-3.6mm) |

1220×2440 |

A/B B/C C+/C C/C C/D D/E |

580 |

Poplar veneer |

poplar / hardwood / pine |

8-14 % |

MR E2 E1 E0 |

+/-0.2mm |

150 / 400 |

|

1/2inch (12-12.7mm) |

1220×2440 |

550 |

Poplar veneer |

poplar / hardwood / pine |

8-14 % |

+/-0.5mm |

70 / 90 |

||

|

5/8inch (15-16mm) |

1220×2440 |

530 |

Poplar veneer |

poplar / hardwood / pine |

8-14 % |

+/-0.5mm |

60 / 70 |

||

|

3/4inch (18-19mm) |

1220×2440 |

520 |

Poplar veneer |

poplar / hardwood / pine |

8-14 % |

+/-0.5mm |

50 / 60 |

ROCPLEX Poplar plywood has been manufactured at our plant in China, for in exces of 15 years and has been used successfully in the Asia, Oceania, Middle east and Souh Amercial.

1)High bending strength and Strong nail holding.

2)Without warping and cracking,steady quality.

3)Moisture-proof and tight construction. No ratten or decay.

4)Low formaldehyde emission.

5)Easy to nail ,saw cutting and drilling. can cut stones into various shapes according to construction needs.

6)The poplar plywood are crafted from real natural wood.

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

10 pallets |

20 CBM |

13000KGS |

12500KGS |

|

40 HQ |

20 pallets |

40 CBM |

25000KGS |

24500KGS |

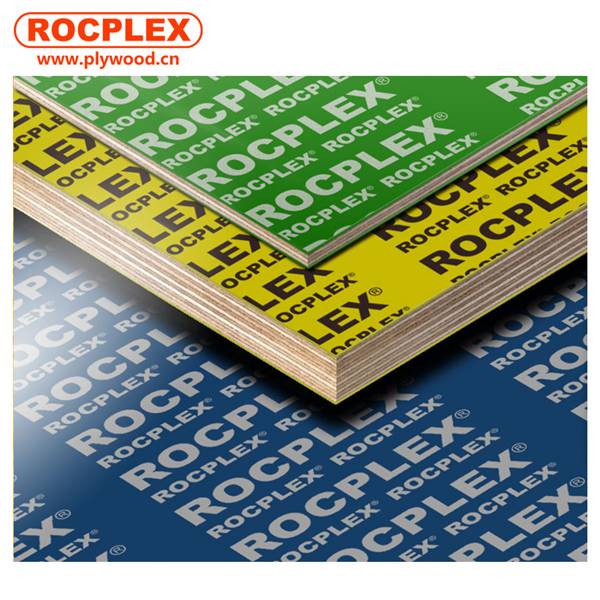

Meanwhile we also can supply you the formwork systerm accessories, commercial plywood , film faced plywood etc.

We specially professional in supplying antislip plywood.

Please contact our sales team for more detailed information regarding chinese plywood.

Product detail pictures:

Related Product Guide:

Questions and answers encountered in the use of plywood plates

China’s plywood production and import and export analysis in 2020: production is mainly wood plywood

Our merchandise are commonly identified and dependable by end users and will meet continually altering financial and social desires for New Fashion Design for Ply Cost - Poplar Plywood 1220mmx2440mm 2.7-21mm – ROC , The product will supply to all over the world, such as: New York, Lithuania, Atlanta, Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!