What is Birch Plywood

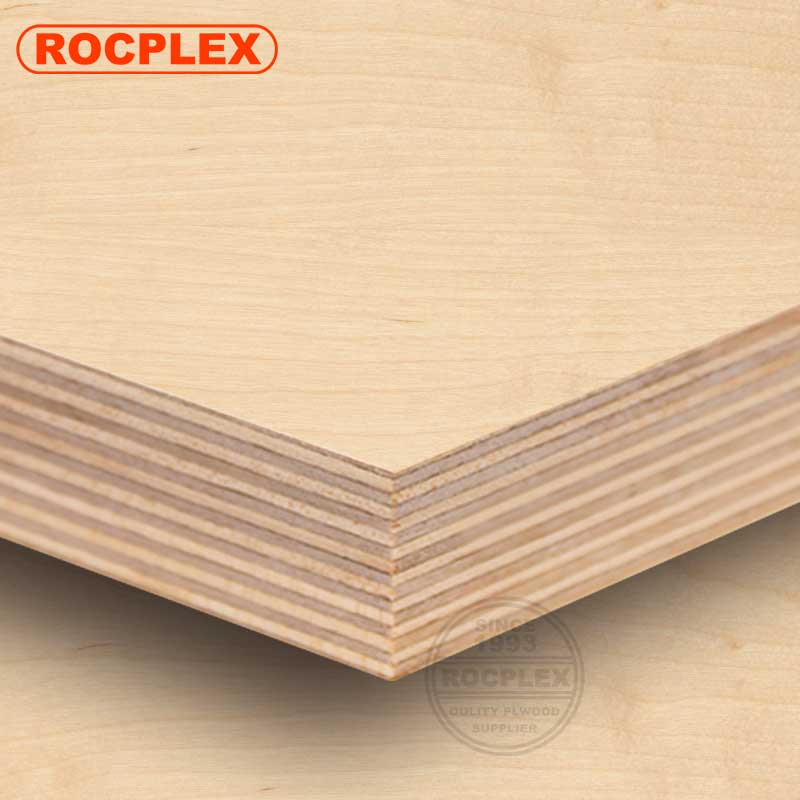

Birch Plywood is an artificial wood board made of natural birch veneer through peeling and recombination. The front side of the Birch Plywood is called the face veneer, the bottom side is called the back veneer, and the middle part is called the core veneer. Birch Plywood is a commonly used board for construction projects and furniture manufacturing. Birch Plywood optimizes the properties of natural wood, increasing the range and properties of wood a lot.

Birch Plywood is one of the commonly used materials for furniture. It is one of the three major wood-based panels. It can also be used for aircraft, ships, trains, automobiles, buildings and packaging boxes. A group of veneer is usually formed by gluing the wood grain directions of adjacent layers perpendicular to each other. Usually, the surface plate and the inner layer are symmetrically arranged on both sides of the center layer or the core. It is a slab made of glued veneers crisscrossed in the direction of the wood grain, and pressed under the condition of heating or no heating. The number of layers is generally odd, and a few are even. The physical and mechanical properties in the vertical and horizontal directions are slightly different. Commonly used Birch Plywood types are three Birch Plywood, five Birch Plywood and so on. Birch Plywood can improve the utilization rate of wood and is a main way to save wood.

Advantages of Birch Plywood

1. Birch Plywood is more stable than natural wood

The Birch Plywood is made of natural logs after peeling and recombining layer by layer, so the stability of Birch Plywood is better than that of natural wood, and it is not easy to crack or bend.

2. Low price

Birch Plywood makes full use of the advantages of natural wood, so the price will be much lower than that of natural wood.

3. Wide range of use

Birch Plywood is not only widely used in construction engineering and furniture manufacturing, but also used in house decoration, aircraft, ships and containers.

Application of Birch Plywood

Birch Plywood more and more widely used in furniture manufacturing, such as cabinets, cabinets, tables, chairs, etc.; interior decoration includes ceilings, wall skirts, and floor linings etc.; concrete building formwork, building components, etc. in engineering construction; as well as vehicle and ship manufacturing and packaging industries.

Type of Birch Plywood

(1) According to the use, it is divided into ordinary Birch Plywood and special Birch Plywood.

(2) Ordinary Birch Plywood is divided into class I Birch Plywood, class II Birch Plywood, and class III Birch Plywood, which are weather-resistant, water-resistant and moisture-resistant Birch Plywood respectively.

(3) Ordinary Birch Plywood is divided into unsanded board and sanded board according to whether the surface is sanded or not.

(4) According to tree species, it is divided into poplar Birch Plywood, birch Birch Plywood, Okoume Birch Plywood, Pine Birch Plywood, EV Birch Plywood.

Specifications of Birch Plywood

Commonly used Birch Plywood Specifications is 1220mmx2440mm (4ftx8ft), and 1250mmx2500mm, 1200mmx2400mm, 915mmx1830mm, etc.

Birch Plywood thickness is generally divided into 2.7mm, 3.6mm, 5.2mm, 6mm, 7mm, 8.5mm, 9mm, 12mm, 15mm, 17mm, 18mm, 21mm, 25mm, 28mm, 30mm

How to choose Birch Plywood

In the production of Birch Plywood, many varieties of colors are derived. The most important one is to paste a thin layer of decorative veneer veneer on the surface of the original Birch Plywood, which is called decorative veneer veneer Birch Plywood, which is referred to as decorative veneer in the market. board or veneer.

It is worth noting that common veneers are divided into natural wood veneer veneers and artificial veneer veneers. Natural wood veneer is a veneer veneer made of precious natural wood by slicing or rotary cutting. Artificial veneer is made of low-priced logs into veneers, which are glued into wooden squares through a certain process, and then sliced ??into decorative veneers with beautiful patterns.

1) Choose Birch Plywood of different types, grades, materials, decorations and formats according to factors such as engineering properties, use parts, and environmental conditions.

2) The decoration should be made of Birch Plywood with veneer veneer of precious wood.

3) The Birch Plywood used for interior decoration of buildings shall comply with the provisions of national standards.

4) The concealed parts that may be damp and the occasions with high waterproof requirements should consider using the Birch Plywood of class I or class II, and the Birch Plywood used outdoors should choose the Birch Plywood of class I.

5) Transparent varnish (also known as clear oil) should be used for panel decoration to retain the natural color and texture of the wood surface. The selection of panel material, pattern and color should be emphasized; if the pattern and color of the panel do not need to be considered, it should also be reasonable according to the environment and cost. Select Birch Plywood grade and category.

Where to Buy Birch Plywood

China is the Largest Origin of Birch Plywood, ROCPLEX Brand Birch Plywood is the Top Grade Formwork Brand in China.

Why Choose ROCPLEX birch plywood:

ROCPLEX is the Largest Manufacturer and Exporter of Birch Plywood and Related Products in China, Which Was Founded in 1993 with 6 Subsidiaries. We Are Now Enjoying 73 Production Lines of Birch Plywood and Fancy Birch Plywood.

25 Year Birch Plywood Manufacturing Experience Provide Stable Quality and Low Price for Difference Require. Rich Export Experience Provide You with Better Service and Document Support, So That Your Products Can Be Easily Cleared.

Post time: Jan-23-2022