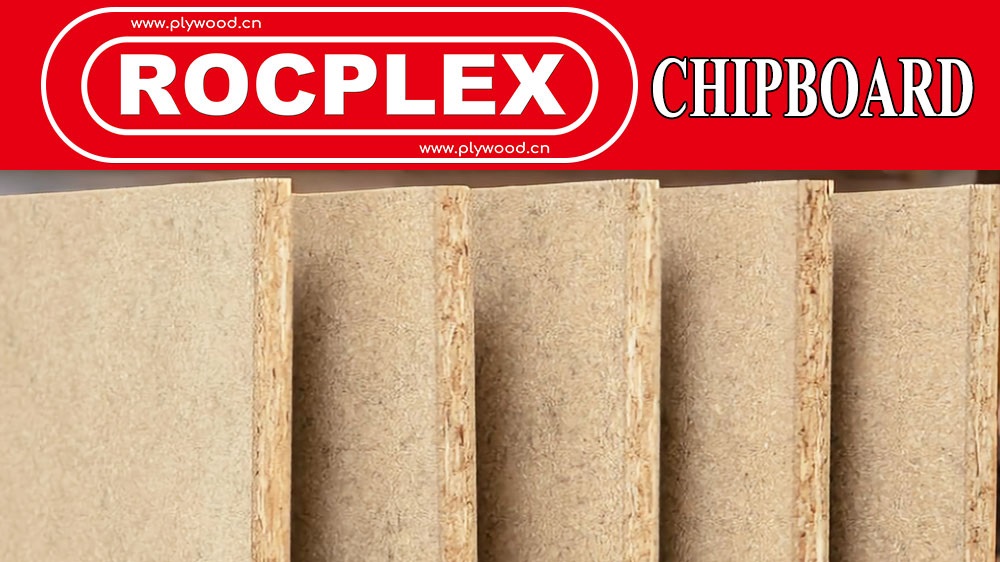

What is Chipboard?

Chipboard, commonly referred to as particle board, is a composite wood product made by compressing wood chips, sawdust, and resin. The mixture is heat-pressed into sheets of varying thickness. Chipboard is valued for its affordability, ease of use, and adaptability across industries like furniture manufacturing, interior design, and construction.

Although lighter and less dense than plywood or MDF board, chipboard serves as an economical alternative, especially where heavy loads or durability are not primary concerns. Available in raw or laminated forms, chipboard can be used for flooring, cabinetry, and even packaging. Its cost-effectiveness has made it increasingly popular in modern projects.

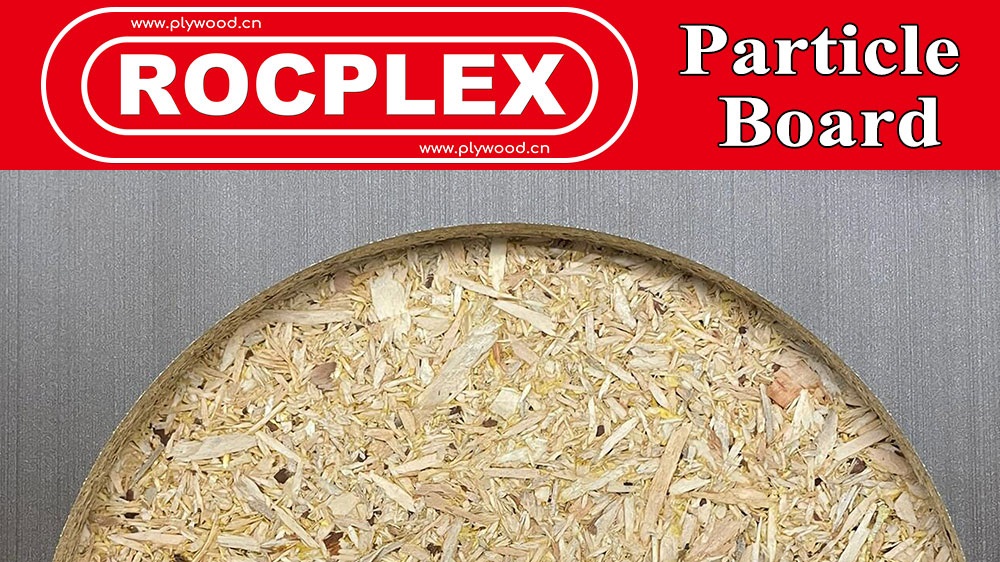

The Composition and Manufacturing of Chipboard

Chipboard is made using a combination of recycled wood materials, such as sawdust, wood chips, and resin adhesives. These components undergo heat pressing to form rigid panels.

Materials Used

- Recycled wood fibers

- Sawdust and fine wood particles

- Adhesive resins like urea formaldehyde

The process reduces waste while ensuring affordability. Manufacturers often use laminated chipboard for enhanced durability and aesthetics, making it a versatile choice for interior applications.

Manufacturing Process

- Wood Sourcing: Waste wood and sawdust are collected.

- Grinding: Materials are ground into uniform-sized particles.

- Adhesive Application: Resin binds the particles together.

- Heat Pressing: The mixture is pressed under high heat and pressure.

- Cutting and Finishing: Sheets are cut to size and finished for specific applications.

Chipboard vs. Other Engineered Wood Products

Chipboard vs. MDF Board

MDF (Medium-Density Fiberboard) is denser and smoother compared to chipboard. MDF board has finer wood fibers, making it ideal for detailed work like furniture molding. Chipboard, while coarser, remains a cost-effective solution for basic applications.

|

Feature |

Chipboard |

MDF Board |

| Cost | Lower | Moderate |

| Density | Medium | High |

| Smoothness | Coarse | Smooth |

| Applications | Flooring, Cabinets | Furniture, Panels |

Chipboard vs. Plywood Sheets

Plywood sheets, made from multiple veneer layers, are stronger and more durable than chipboard. However, plywood is more expensive and heavier. Chipboard remains preferable for temporary or lightweight structures.

|

Feature |

Chipboard |

Plywood Sheets |

| Strength | Moderate | High |

| Weight | Light | Heavy |

| Price | Affordable | Costly |

| Best Use | Cabinets, Shelves | Construction Panels |

Laminated Chipboard for Enhanced Utility

Laminated chipboard features a decorative layer that improves aesthetics and durability. It’s perfect for furniture and interior décor. Compared to raw chipboard, laminated options resist moisture and wear better.

Applications of Chipboard in Construction and Interior Design

Chipboard Flooring

Chipboard panels serve as excellent underlayment for flooring. Its smooth, even surface provides stability for carpets and vinyl flooring. Chipboard flooring is easy to install and highly affordable.

Key Features:

- Flat and even surface

- Cost-effective underlayment

- Ideal for temporary flooring solutions

Furniture Manufacturing

Chipboard is extensively used in low-cost furniture. Its lightweight structure makes it ideal for cabinets, shelving units, and wardrobes. Laminated chipboard enhances durability and aesthetic appeal.

Benefits for Furniture:

- Affordable material for large-scale production

- Easily customized with laminates or veneers

- Reduces overall production costs

Packaging and Pallets

Chipboard is an eco-friendly packaging option. Its lightweight properties make it suitable for product packaging, protective boxes, and shipping pallets.

Advantages:

- Reduces material waste

- Cost-effective for bulk packaging

- Lightweight for easy transport

The Advantages of Using Chipboard

Cost-Effectiveness

Chipboard is one of the most affordable engineered wood products. Its manufacturing process utilizes recycled wood materials, significantly reducing production costs.

Eco-Friendliness

Using recycled wood fibers minimizes environmental impact. Chipboard’s production requires fewer raw timber resources compared to plywood sheets.

Ease of Use

Chipboard is lightweight and easy to cut, making it user-friendly for both professionals and DIY enthusiasts. Laminated chipboard further simplifies finishing processes.

Versatility

From furniture to flooring, chipboard fits a wide range of applications. Laminated options offer additional durability, making it a versatile material for modern projects.

Challenges and Limitations of Chipboard

Moisture Sensitivity

Raw chipboard absorbs moisture quickly, leading to swelling and damage. Laminated chipboard offers better resistance but remains unsuitable for wet environments.

Solution: Use moisture-resistant variants for areas prone to dampness.

Durability Concerns

Compared to plywood sheets, chipboard lacks the same structural strength. It is best used for lightweight projects or temporary installations.

Solution: Combine chipboard with laminates or veneers for enhanced strength.

Chipboard in Modern Construction Trends

As construction methods evolve, chipboard has found its place in cost-effective and sustainable projects. It is commonly used in residential buildings, office spaces, and retail fit-outs. Its lightweight properties make it a preferred choice for temporary structures and large-scale paneling.

Temporary Structures

Chipboard offers a reliable material for constructing temporary buildings or partition walls. It is affordable and easy to replace when necessary.

Examples:

- Exhibition booths

- Pop-up retail structures

- Temporary office partitions

Sustainable Design

The construction industry increasingly focuses on sustainability. Chipboard aligns with this trend as it utilizes recycled materials, minimizing the demand for virgin timber. Laminated chipboard further extends its lifespan, reducing long-term waste.

Laminated Chipboard: A Focus on Durability

Laminated chipboard combines chipboard’s cost-effectiveness with improved durability and aesthetics. By adding a laminated surface, the board resists moisture, scratches, and general wear.

Advantages of Laminated Chipboard

- Enhanced Strength: Suitable for furniture and shelving.

- Improved Aesthetics: Available in various colors and patterns.

- Moisture Resistance: Reduces the risk of swelling in humid areas.

- Kitchen cabinetry

- Office desks and workstations

- Wall paneling and decorative cladding

Applications

Chipboard Flooring: Affordable and Reliable

Chipboard flooring has become a go-to choice for builders seeking cost-efficient underlayment. Its smooth surface allows for seamless installation of carpets, vinyl, or laminate flooring.

Benefits:

- Cost-Effective: Reduces flooring expenses.

- Quick Installation: Lightweight boards are easy to handle.

- Stable Surface: Provides a flat base for finished flooring.

Key Considerations:

For areas prone to moisture, opting for moisture-resistant chipboard is essential. Standard chipboard may swell when exposed to damp conditions.

How to Choose the Right Chipboard

Selecting the right chipboard depends on the project requirements. Factors to consider include thickness, density, and surface finish.

Key Criteria for Selection

- Thickness: Ranges from 6mm to 25mm; thicker boards offer greater stability.

- Surface: Raw chipboard for basic applications; laminated chipboard for furniture and décor.

- Moisture Resistance: Opt for moisture-resistant chipboard in humid conditions.

Common Types:

- Standard Chipboard: Best for dry indoor environments.

- Moisture-Resistant Chipboard: Suitable for kitchens and bathrooms.

- Laminated Chipboard: Ideal for furniture and decorative use.

Chipboard’s Role in Sustainable Construction

Sustainability is a driving force in today’s construction industry. Chipboard contributes to eco-friendly practices by reusing wood waste and reducing the need for fresh timber.

Eco-Friendly Benefits

- Waste Reduction: Made from recycled wood products.

- Carbon Footprint: Lower energy consumption during production.

- Sustainable Alternatives: Chipboard replaces costlier materials like solid wood.

Future Trends

The industry is exploring enhanced chipboard variants with improved durability and moisture resistance. Innovations such as fire-retardant and formaldehyde-free chipboard panels are becoming increasingly common.

Maintenance and Care of Chipboard Products

Proper maintenance ensures chipboard retains its quality and functionality over time.

Tips for Maintenance

- Keep Dry: Avoid exposing raw chipboard to moisture.

- Use Laminates: For surfaces prone to wear, laminated chipboard offers added protection.

- Handle with Care: Avoid heavy loads that may cause chipping or breakage.

Cleaning and Repairs

- Use a dry cloth to clean laminated surfaces.

- For minor chips, wood fillers or adhesives can restore functionality.

Why Chipboard Remains a Top Choice

Chipboard continues to be a leading choice for cost-effective and versatile construction solutions. It is ideal for furniture manufacturing, flooring, and sustainable building projects. Its affordability and ease of use make it a preferred option for both professionals and DIY enthusiasts.

Key Takeaways

- Affordable alternative to plywood sheets and MDF board.

- Versatile applications in construction, furniture, and packaging.

- Laminated chipboard offers improved durability and aesthetics.

- Eco-friendly option that supports sustainable building practices.

As demand for sustainable and economical materials grows, chipboard will remain a staple in the construction and design industries.

Post time: Jan-04-2025