What Are Chipboard Sheets?

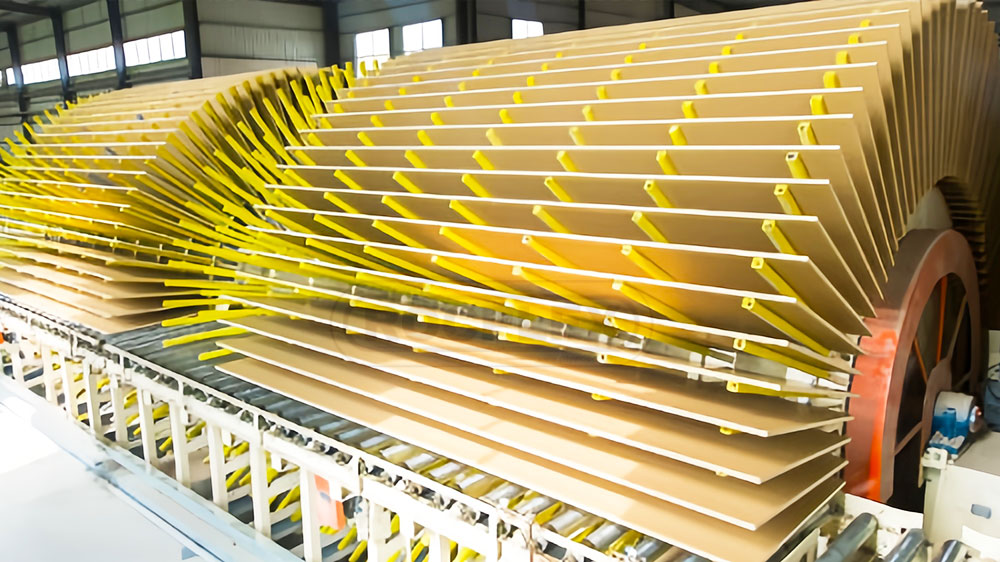

Chipboard sheets are engineered wood boards produced by compressing wood particles with adhesive resins under heat and pressure. Manufacturers typically use sawdust, wood chips, or recycled wood waste in this process. This method creates a sturdy, uniform board with consistent strength.

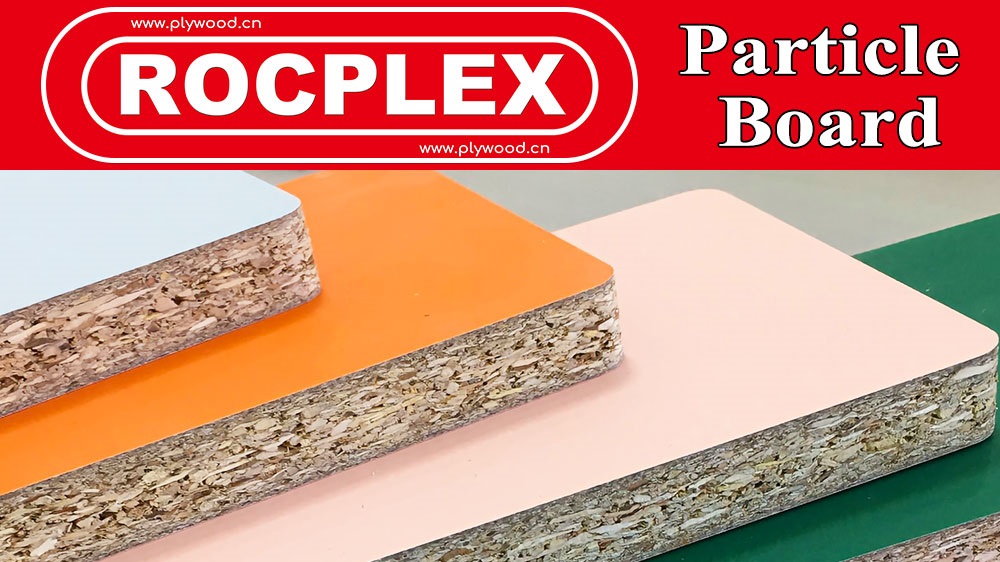

Chipboard sheets are available in multiple grades and thicknesses, making them suitable for various projects. Standard chipboard works well for light-duty tasks like backing boards and decorative paneling. High-density chipboard offers enhanced strength for heavier applications such as flooring substrates and countertops. Laminated chipboard combines strength with a decorative finish, perfect for furniture surfaces and custom designs.

Because chipboard sheets repurpose wood waste, they reduce deforestation and promote sustainable construction practices. This eco-friendly feature makes chipboard sheets an ideal choice for cost-effective and environmentally conscious projects.

Benefits of Chipboard Sheets

1. Affordable and Cost-Effective

Chipboard sheets offer a budget-friendly alternative to solid wood. Manufacturers create these boards using recycled wood waste, reducing production costs. Their affordability makes chipboard sheets ideal for large-scale projects, furniture production, and DIY improvements.

2. Durable and Stable

Chipboard sheets provide strong structural stability. The compressed wood particles create a dense, uniform structure that resists bending and warping. High-density chipboard excels in demanding applications, supporting heavy loads without compromising stability.

3. Easy to Work With

Chipboard sheets are easy to cut, drill, and shape using standard woodworking tools. Their smooth, even surface allows for precise cuts and clean edges. This makes chipboard sheets suitable for custom designs and detailed carpentry.

4. Versatile in Design

Laminated chipboard sheets provide stylish finishes that enhance visual appeal. These sheets are available in various colors, wood grain patterns, and textures, allowing designers to create decorative surfaces that mimic solid wood.

5. Eco-Friendly Production

Chipboard sheets are environmentally responsible materials. Manufacturers repurpose wood waste such as sawdust and wood chips to produce chipboard. This recycling process minimizes waste and promotes sustainable forestry practices.

Applications of Chipboard Sheets

1. Furniture Manufacturing

Chipboard sheets are widely used in furniture production. They are ideal for creating wardrobes, bookshelves, tables, and kitchen cabinets. Flat-pack furniture brands frequently use chipboard sheets due to their affordability, lightweight structure, and ease of assembly.

2. Flooring Substrates

Chipboard sheets are commonly installed as underlayment for carpet, laminate, and vinyl flooring. Their smooth, stable surface ensures excellent support for floor coverings. Moisture-resistant chipboard sheets are ideal for kitchens, bathrooms, and basements.

3. Decorative Wall Panels

Laminated chipboard sheets provide an attractive alternative to traditional wall panels. They are available in a variety of patterns, colors, and textures, making them suitable for enhancing both residential and commercial interiors.

4. Packaging Solutions

Chipboard sheets provide strength and rigidity for industrial packaging. They are ideal for reinforcing cartons and supporting fragile items during transport.

5. Exhibition Stands and Displays

Chipboard sheets are widely used for custom trade show displays, signage, and presentation backdrops. Their lightweight properties simplify setup, transport, and dismantling for event displays.

Types of Chipboard Sheets

1. Standard Chipboard

Standard chipboard sheets are ideal for lightweight, non-load-bearing structures such as decorative panels, storage units, and temporary installations.

2. High-Density Chipboard

High-density chipboard sheets provide superior strength for heavy-duty applications. They are suitable for shelving, countertops, and structural furniture designs.

3. Moisture-Resistant Chipboard

Moisture-resistant chipboard sheets are treated with water-repellent resins to enhance durability in damp environments. These boards are suitable for kitchens, bathrooms, and basements.

4. Fire-Retardant Chipboard

Fire-retardant chipboard sheets contain flame-resistant additives that reduce fire spread. These boards are ideal for public spaces, offices, and commercial environments that require enhanced fire protection.

5. Laminated Chipboard

Laminated chipboard sheets combine durability with aesthetic appeal. These boards feature decorative finishes in wood grain textures, solid colors, or custom patterns, ideal for visible furniture elements.

How to Install Chipboard Sheets

1. Surface Preparation

Ensure the installation surface is clean, dry, and level. Remove dust, debris, and uneven flooring for optimal results.

2. Measuring and Cutting

Mark measurements carefully before cutting chipboard sheets. Use sharp blades or circular saws for smooth, precise cuts.

3. Drilling and Fastening

Pre-drill holes before inserting screws to prevent the material from splitting. For added stability, combine screws with wood glue.

4. Sealing Exposed Edges

Exposed chipboard edges are vulnerable to moisture. Apply edge banding, veneer strips, or waterproof sealants to enhance durability.

5. Applying a Protective Coating

For long-term protection, apply varnish, paint, or laminate coatings. This additional layer resists scratches, stains, and moisture.

Maintenance and Care

1. Routine Cleaning

Wipe chipboard surfaces regularly using a dry or slightly damp cloth. For laminated chipboard, use non-abrasive cleaners to protect the decorative finish.

2. Moisture Control

Avoid prolonged water exposure. For areas prone to moisture, choose moisture-resistant chipboard sheets and apply waterproof sealants.

3. Repairing Damage

For minor dents or chips, use wood filler to restore the surface. Once dry, sand the area before refinishing with paint or veneer.

Environmental Impact

Chipboard sheets are an eco-conscious material that minimizes wood waste. Manufacturers recycle sawdust, wood chips, and timber offcuts to create these boards. By repurposing wood waste, chipboard sheets help reduce deforestation and landfill waste.

The energy-efficient production of chipboard sheets aligns with modern sustainability trends. Many particle board are also certified by the Forest Stewardship Council (FSC), ensuring responsible forestry practices.

Common Mistakes to Avoid

1. Ignoring Edge Sealing

Failing to seal chipboard edges may lead to swelling and water damage. Always protect edges with waterproof sealants or edge banding.

2. Overloading Surfaces

Avoid placing heavy loads on standard chipboard sheets. For weight-bearing applications, use high-density chipboard to ensure stability.

3. Incorrect Storage

Store chipboard sheets in dry, climate-controlled environments. Improper storage may cause warping or weakening of the boards.

Chipboard sheets are durable, affordable

Chipboard sheets are a practical, affordable, and versatile material widely used in furniture production, flooring, and decorative projects. With options like particle board sheets, laminated chipboard, and moisture-resistant varieties, chipboard sheets provide customized solutions for both residential and commercial designs.

By combining durability, flexibility, and eco-friendly properties, chipboard sheets remain a top choice for contractors, interior designers, and DIY enthusiasts. Whether creating stylish furniture or improving structural stability, chipboard sheets offer long-term performance and exceptional value.

For additional guidance on selecting, cutting, or maintaining chipboard sheets, feel free to ask!

Post time: Mar-22-2025