What is Filmface Plywood?

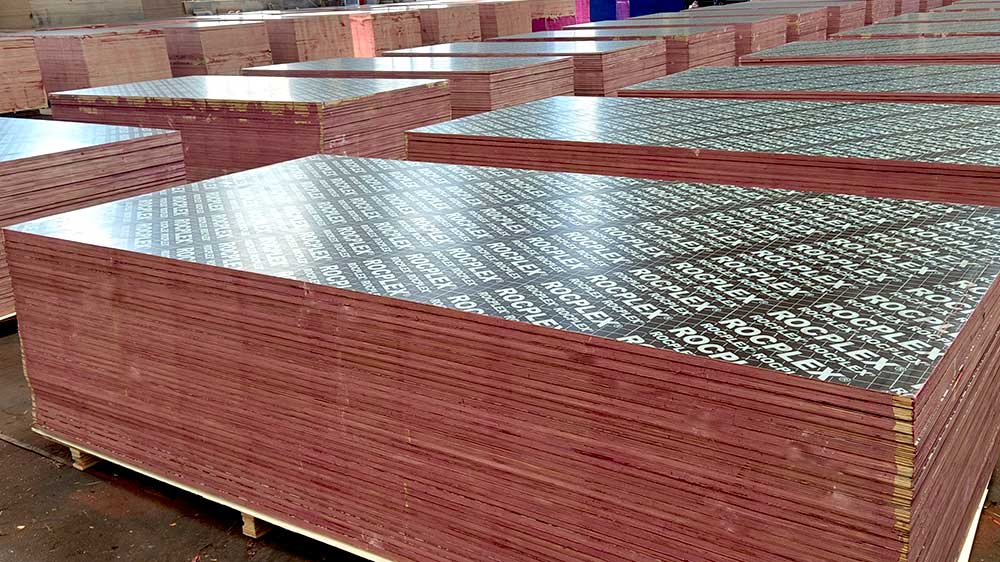

Filmface plywood, a high-quality plywood coated with a film, is an integral material in the construction industry. Known for its strength and durability, this plywood type withstands harsh conditions, making it ideal for concrete formwork and shuttering applications. Its unique film coating not only enhances its water resistance but also provides a smooth surface, crucial for concrete casting.

Filmface Plywood in Construction

The Advantages of Using Filmface Plywood

Filmface plywood offers numerous benefits in construction. Its durability under extreme conditions and resistance to moisture and wear are paramount. This material is repeatedly used in concrete formwork, providing cost-effectiveness over time. Additionally, the smooth finish it imparts on concrete surfaces reduces the need for further plastering, saving time and resources.

Shuttering Plywood and Concrete Forms

Shuttering plywood, a synonym for filmface plywood, plays a crucial role in molding concrete structures. Its ability to withstand the pressure of wet concrete and maintain shape makes it a reliable choice for complex construction tasks. The versatility of filmface plywood in various forms, including customized shapes for concrete formwork, highlights its adaptability in diverse building scenarios.

The Environmental Impact

Filmface plywood is not only efficient but also eco-friendly. Sourced from sustainable forests, it contributes to responsible construction practices. Its reusability further enhances its environmental appeal, reducing the carbon footprint of building projects.

Technical Aspects of Filmface Plywood

Manufacturing Process

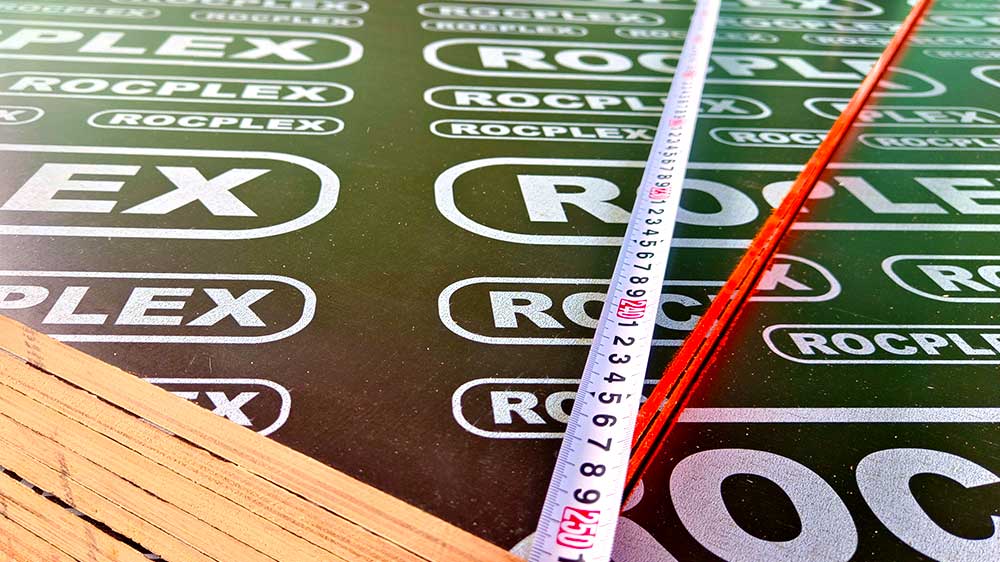

The production of formwork plywood involves bonding layers of wood veneers with durable adhesives, topped with a phenolic film. This process ensures uniformity in strength and size, essential for precise construction work.

Quality Standards and Certification

Adherence to quality standards is crucial in the production of filmface plywood. Certifications like ISO and CE mark the product’s compliance with international safety and quality norms, assuring builders of its reliability.

Applications in Modern Construction

Versatility in Various Projects

Filmface plywood’s versatility extends to numerous construction projects. From large-scale buildings to intricate architectural designs, its adaptability is unmatched. This material is particularly effective in forming smooth concrete surfaces for aesthetic and functional purposes.

Innovation in Design and Architecture

Architects and designers increasingly turn to filmface plywood for innovative construction solutions. Its flexibility in shaping and strength in structure open new possibilities in modern architectural design.

Economic Impact of Filmface Plywood

Cost-Effectiveness in Construction

The economic benefits of shuttering plywood are significant. Its durability and reusability lead to cost savings over time, as it can be used multiple times in various projects without losing its structural integrity. This aspect is particularly important in large-scale construction projects where material costs can escalate quickly.

Global Market Trends

The global market for filmface plywood is witnessing a steady growth. Driven by the increasing demand in construction and infrastructure development, particularly in emerging economies, the market dynamics reflect a shift towards more sustainable and efficient building materials.

Supply Chain and Distribution

The supply chain of filmface plywood spans from sustainable forestry practices to global distribution networks. Efficient supply chain management ensures the availability of this material worldwide, catering to the growing needs of the construction industry.

Technical Innovations in Filmface Plywood

Advances in Manufacturing Techniques

The manufacturing process of filmface plywood has seen significant advancements. Modern techniques involve the use of superior adhesives and high-grade wood veneers, enhancing the plywood’s overall quality and performance. These innovations contribute to the material’s increased resistance to environmental factors, making it more durable and reliable.

Research and Development

Continuous research and development in the field of construction materials have led to improvements in filmface plywood. These advancements focus on enhancing its water resistance, load-bearing capacity, and overall sustainability, further cementing its role in modern construction practices.

Health and Safety in Using Filmface Plywood

Safety Standards

Adherence to health and safety standards is paramount in the usage of filmface plywood. This involves ensuring that the materials used in its production are non-toxic and that the final product is safe for use in various environments, particularly in residential construction.

Worker Safety

The ease of handling and installation of filmface plywood contributes to worker safety. Its predictable and uniform dimensions reduce the risk of accidents on-site, making it a preferred choice among construction professionals.

The Future of Filmface Plywood in Construction

Emerging Technologies and Applications

The future of filmface plywood in construction is bright, with emerging technologies expanding its applications. Innovations in material science may lead to even more durable and versatile forms of filmface plywood, opening new avenues in construction techniques and design.

Sustainability and Green Building

As the focus on sustainable building practices intensifies, filmface plywood stands out for its eco-friendly attributes. Future developments are likely to emphasize even more on its environmental benefits, aligning with global efforts towards green building practices.

FAQs About Filmface Plywood

Is Filmface Plywood Waterproof?

Filmface plywood is highly water-resistant, thanks to its phenolic film coating. This characteristic makes it ideal for use in environments where moisture is a concern.

What is Phenolic Film Faced Plywood?

Phenolic film faced plywood is a type of filmface plywood coated with a phenolic resin film. This coating enhances its durability, water resistance, and smooth finish.

Is Phenolic Board Waterproof?

Phenolic boards, including filmface plywood with a phenolic coating, are water-resistant, making them suitable for outdoor and moisture-prone environments.

Why is Phenolic Filmface Plywood So Expensive?

The cost of phenolic filmface plywood is higher due to its superior quality, durability, and the specialized manufacturing process involved. Its long lifespan and reusability often offset the initial investment.

Integrating Film Faced Plywood in Sustainable Practices

Eco-friendly Manufacturing Processes

The production of filmface plywood is increasingly leaning towards more eco-friendly processes. This includes using sustainable wood sources and reducing emissions during manufacturing. As environmental concerns take center stage globally, the shift towards greener production methods is becoming a key factor in the industry.

Recycling and Reusability

One of the standout features of filmface plywood is its recyclability and reusability. This aspect not only contributes to environmental sustainability but also offers economic benefits by reducing the need for frequent replacements.

Impact on Global Construction Standards

Raising the Bar in Building Quality

The use of filmface plywood in construction has raised the standards of building quality. Its consistent performance, durability, and aesthetic finish contribute to higher-quality constructions, meeting the demands of modern architecture and design.

Compliance with International Building Codes

Filmface plywood complies with various international building codes and standards, ensuring its suitability for use in diverse construction environments. This compliance further boosts its acceptance and usage worldwide.

Customer Insights and Market Feedback

User Experience and Satisfaction

Feedback from users of filmface plywood, including contractors, architects, and builders, has been overwhelmingly positive. Its ease of use, performance, and finish quality are frequently highlighted, underscoring its growing popularity in the construction sector.

Adaptation to Market Needs

The filmface plywood industry has shown remarkable adaptability to market needs. From offering various thicknesses and sizes to custom solutions for unique projects, manufacturers are continuously innovating to meet the evolving demands of the construction industry.

Advancing Education and Awareness

Training and Workshops

Educational initiatives, such as training programs and workshops for construction professionals, are essential in maximizing the benefits of filmface plywood. These programs focus on proper handling, installation techniques, and safety practices, ensuring optimal use of this material.

Promotional Campaigns

Promotional campaigns play a significant role in increasing awareness about the advantages of filmface plywood. These campaigns not only educate the market about its applications but also highlight its environmental benefits, appealing to a broader audience.

Collaboration and Partnerships

Industry Alliances

Collaborations between manufacturers, suppliers, and construction firms are vital in advancing the use of filmface plywood. These partnerships lead to better supply chain efficiencies, innovative product development, and more sustainable practices.

Global Outreach

The global outreach of filmface plywood manufacturers includes participation in international trade shows, conferences, and exhibitions. This global presence not only expands the market but also fosters knowledge sharing and industry advancements.

Looking Ahead: The Ongoing Evolution of Filmface Plywood

The journey of filmface plywood is one of continuous evolution. As new technologies emerge and environmental considerations become more pressing, this material is poised to play an even more significant role in the construction industry. Its adaptability, durability, and sustainable qualities align perfectly with the future of building and design, making it a cornerstone in the development of modern infrastructure.

Filmface Plywood: Paving the Way for Future Construction Endeavors.

Post time: Mar-24-2024