What is Formply?

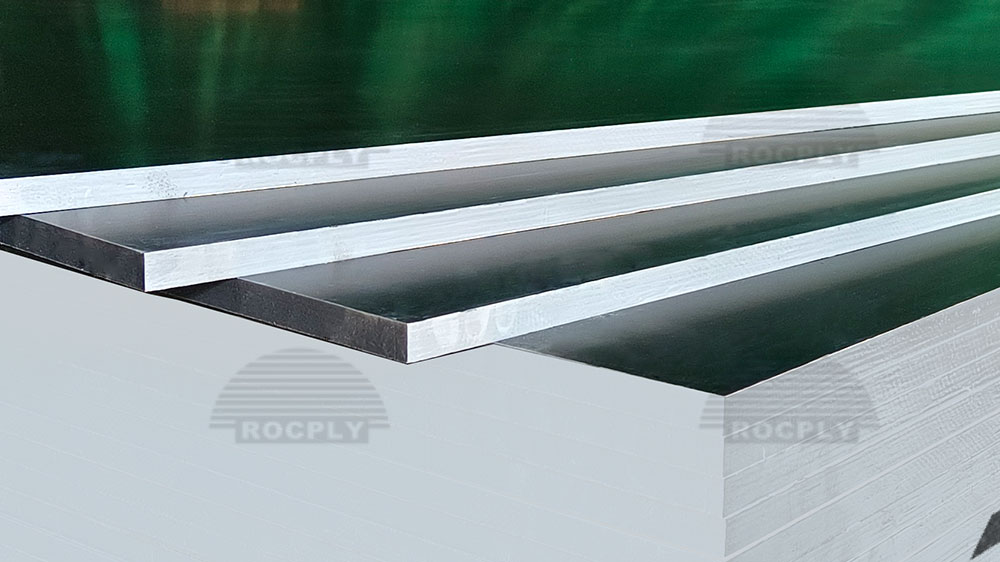

Formply is a high-grade plywood specifically engineered for the construction industry, is revolutionizing building practices worldwide. Known for its strength and durability, formply is used as a mold for poured concrete, shaping foundations, walls, and other structural elements with precision. Its unique layered structure, coated with a film to resist moisture, makes it a preferred choice for concrete formwork, ensuring reliability and consistency in construction projects.

The Rise of Formply in Modern Construction

The Unmatched Durability of Formply

In the contemporary building sector, formply has become synonymous with strength and longevity. Its ability to withstand high pressure and adverse environmental conditions makes it ideal for creating sturdy concrete forms. This durability not only ensures the safety and integrity of structures but also translates to cost-effectiveness, as formply can be reused multiple times.

Innovation in Concrete Formwork

The use of formply in concrete formwork is a testament to its versatility. It provides a smooth surface that results in aesthetically pleasing concrete finishes. Moreover, formply’s adaptability to various shapes and sizes makes it suitable for complex architectural designs, fostering creativity and innovation in construction.

The Evolution of Building Materials

Shuttering Plywood: An Alternative Approach

Shuttering plywood, a close relative of formply, is also widely used in concrete formwork. While similar in function, it differs slightly in terms of material composition and surface coating, offering a cost-effective alternative for certain construction needs.

The Role of Film Faced Plywood

Film faced plywood, often used interchangeably with formply, adds another dimension to construction material choices. Its film coating provides excellent resistance to moisture and chemicals, making it a durable option for outdoor and high-moisture environments.

Environmental and Economic Impact

Sustainability and Eco-friendliness

The construction industry is increasingly focusing on sustainable practices, and formply plays a significant role in this shift. Made from renewable resources and often recyclable, formply aligns with eco-friendly building practices, reducing the environmental footprint of construction projects.

Cost-Effectiveness and Efficiency

Formply’s reusability not only contributes to environmental sustainability but also offers economic advantages. Its long lifespan and ability to withstand multiple uses without significant wear and tear make it a cost-effective solution for builders and developers.

Technological Advancements in Formply Use

Integrating Technology with Traditional Materials

The integration of technology in formply usage marks a significant advancement in construction methodologies. Modern techniques like Computer Numerical Control (CNC) cutting allow for precise shaping of formply, enabling custom designs and intricate detailing in concrete structures. This technological synergy enhances the functionality of formply, making it an indispensable tool in contemporary construction.

Improving Safety Standards

Formply’s contribution to safety in construction cannot be overstated. Its robustness ensures stability in concrete formwork, significantly reducing the risk of accidents. Enhanced safety protocols, coupled with the material’s reliability, elevate the overall safety standards in the building industry.

Chapter 5: Formply in Architectural Design

Enabling Complex Architectural Forms

The flexibility and strength of formply have opened new avenues in architectural design. Architects now have the freedom to explore more complex shapes and structures, knowing that formply can accommodate these innovative designs. This material has been instrumental in realizing some of the most avant-garde architectural projects in recent years.

Aesthetic Contributions

Beyond its structural benefits, formply also contributes aesthetically. The smooth finish it imparts to concrete surfaces is highly valued in modern architecture, where clean lines and smooth textures are often desired. This aesthetic appeal is yet another reason for its widespread use in high-profile projects.

Comparing Formply with Traditional Building Materials

Formply vs. Traditional Plywood

While traditional plywood has its place in construction, formply stands out for its specific design for concrete formwork. Its moisture-resistant layers and durable surface coating give it a distinct advantage over regular plywood in terms of longevity and efficiency in concrete-related applications.

Advantages Over Metal Forms

Metal forms, another common choice in concrete formwork, are known for their strength. However, formply offers a lighter, more adaptable, and cost-effective alternative. Its ease of handling and cutting, combined with its reusability, makes it a preferred choice in many construction scenarios.

Future Trends and Predictions

Innovations in Material Composition

The future of formply looks bright, with ongoing research into enhancing its properties. Innovations in material science promise to make formply even more resilient, eco-friendly, and adaptable to various construction needs. These advancements are set to redefine the standards of building materials.

Expanding Applications

As the construction industry evolves, the applications of formply are expanding beyond traditional formwork. Its use in temporary structures, interior design, and even in artistic installations indicates a growing recognition of its versatility and potential in various fields.

Global Market Trends and Formply

The Rising Demand in Emerging Economies

Emerging economies are witnessing a surge in construction activities, consequently elevating the demand for formply. Rapid urbanization and infrastructural development in these regions are key drivers of this trend. The adaptability and cost-effectiveness of formply make it particularly appealing in markets where economic efficiency is paramount.

International Standards and Trade

The global market for formply is also influenced by international trade and standardization. As more countries adopt stringent building standards, the demand for high-quality construction materials like formply increases. This trend is fostering an environment of innovation and quality assurance in the production of formply, benefiting both manufacturers and consumers.

Challenges and Solutions in Formply Usage

Addressing Environmental Concerns

While formply is relatively eco-friendly, the industry faces challenges regarding sustainable sourcing and disposal. Manufacturers are increasingly focusing on sustainable forestry practices and exploring recycling options to address these concerns. This shift towards environmental stewardship is crucial in maintaining formply’s relevance in an eco-conscious market.

Overcoming Supply Chain Hurdles

Supply chain management is critical in the formply industry, especially considering its growing global demand. Strategies to streamline logistics, reduce transportation costs, and ensure timely delivery are being implemented. These efforts are vital in maintaining the balance between supply and demand, ensuring formply’s accessibility and affordability.

The Role of Formply in Educational and Training Programs

Incorporating Formply in Construction Education

Recognizing the importance of formply in modern construction, educational institutions are integrating its study into construction and architecture curricula. This education not only includes the material’s properties and uses but also covers sustainable practices and safety protocols, preparing the next generation of builders and designers.

Training Workforce for Specialized Use

On-the-job training programs are increasingly focusing on the specialized use of formply. These programs aim to equip the workforce with the skills needed to effectively work with formply, ensuring safety and maximizing the material’s potential in various construction scenarios.

Consumer Awareness and Market Perception

Building Consumer Trust

The construction industry is working towards building greater consumer awareness and trust in formply. Through transparent communication about the benefits and limitations of formply, consumers are becoming more informed and confident in choosing this material for their projects.

Market Perception and Branding

The market perception of formply is evolving, with many brands positioning it as a premium, yet cost-effective, construction material. Effective branding strategies are enhancing its reputation, making it a sought-after material in both residential and commercial construction projects.

Impact of Formply in Construction

Formply, with its robustness, versatility, and growing applications, is undeniably shaping the future of construction. From revolutionizing concrete formwork to expanding into new markets and applications, its impact is far-reaching. As the industry continues to innovate and embrace sustainable practices, formply is set to remain a key player in building a more efficient, safe, and sustainable world.

FAQs:

What is the difference between plywood and Formply?

- Formply is a specific type of plywood designed for concrete formwork, with greater strength and moisture resistance than regular plywood.

Is formwork ply waterproof?

- While not entirely waterproof, formwork ply is highly moisture-resistant, making it suitable for concrete formwork.

How do you make ply waterproof?

- Plywood can be made more water-resistant through the application of waterproof coatings or by using moisture-resistant adhesives during its manufacture.

Can plywood survive rain?

- Regular plywood can withstand rain to some extent, but prolonged exposure can lead to damage. Moisture-resistant varieties like formply are better suited for rain exposure.

Which plywood is most waterproof?

- Marine plywood and film faced plywood are among the most water-resistant types, often used in applications requiring high moisture resistance.

How do you know if plywood is waterproof?

- Check for labels indicating moisture resistance or specific uses like marine or exterior grade, which suggest higher water resistance.

Post time: Jan-22-2024