Unmatched Quality of Marine Plywood

When it comes to marine construction, quality and durability are paramount. ROCPLEX Marine Plywood stands out as the top choice for builders and engineers alike. This high-quality plywood is designed to withstand the harshest marine environments, ensuring longevity and reliability in every project.

Why Choose Marine Plywood?

Marine plywood is specially crafted to resist water damage, rot, and decay, making it the go-to material for boats, docks, and other marine structures. Unlike regular plywood, marine plywood uses waterproof glue and has no core voids, ensuring maximum strength and stability. ROCPLEX Marine Plywood takes these benefits a step further, providing unmatched quality that meets the highest industry standards.

Key Features of ROCPLEX Marine Plywood

- Superior Water Resistance: ROCPLEX Marine Plywood is treated to resist water absorption, preventing warping and deterioration even in the most humid conditions.

- High Strength and Stability: Constructed with multiple layers of high-grade veneers, this plywood offers exceptional strength and rigidity, making it ideal for demanding marine applications.

- Smooth Finish: The smooth, sanded surface of ROCPLEX Marine Plywood ensures easy handling and a flawless finish, perfect for both structural and aesthetic applications.

- Eco-Friendly Production: ROCPLEX is committed to sustainable practices, using responsibly sourced timber and eco-friendly adhesives in the production of their marine plywood.

Applications of Marine Plywood

ROCPLEX Marine Plywood is versatile and can be used in a variety of marine and non-marine applications. Here are some of the most common uses:

Boat Building

One of the primary uses of marine plywood is in boat building. Its strength, durability, and water resistance make it ideal for constructing hulls, decks, and other boat components. ROCPLEX Marine Plywood ensures that every boat built with it can withstand the test of time and the harsh conditions of the sea.

Docks and Piers

Marine plywood is also perfect for building docks and piers. These structures are constantly exposed to water and must be able to endure both the elements and heavy use. ROCPLEX Marine Plywood’s robust construction guarantees long-lasting performance in these demanding environments.

Outdoor Furniture

In addition to marine applications, ROCPLEX Marine Plywood is great for making outdoor furniture. Its resistance to moisture and decay ensures that garden furniture, park benches, and outdoor tables maintain their integrity and appearance over the years.

Bathrooms and Kitchens

ROCPLEX Marine Plywood is an excellent choice for interior applications where moisture is a concern, such as in bathrooms and kitchens. Its water-resistant properties prevent swelling and warping, ensuring that cabinets, countertops, and flooring stay in top condition.

Benefits of Using ROCPLEX Marine Plywood

Choosing ROCPLEX Marine Plywood for your construction projects comes with numerous benefits:

- Longevity: Marine plywood’s ability to withstand water and harsh conditions ensures that structures last longer, reducing the need for frequent repairs or replacements.

- Safety: The high strength and stability of ROCPLEX Marine Plywood enhance the safety and reliability of marine constructions, providing peace of mind to builders and users.

- Aesthetics: The smooth surface and high-quality finish of this plywood contribute to the overall aesthetic appeal of projects, whether they are functional or decorative.

- Cost-Effectiveness: While the initial cost may be higher than regular plywood, the durability and low maintenance requirements of ROCPLEX Marine Plywood make it a cost-effective choice in the long run.

Product Specifications

ROCPLEX Marine Plywood comes in various thicknesses and sizes to meet different project requirements. It is available in standard sheet sizes and can be customized to specific dimensions if needed.

- Thickness: Available in 6mm, 9mm, 12mm, 18mm, and 25mm

- Sheet Size: Standard sizes include 2440mm x 1220mm (8’ x 4’) and 3050mm x 1525mm (10’ x 5’)

- Core: Composed of high-quality veneers with no core voids

- Glue: Waterproof adhesive meeting WBP (Weather and Boil Proof) standards

Installation Tips for Marine Plywood

To ensure the best performance and longevity of ROCPLEX Marine Plywood, follow these installation tips:

- Sealing Edges: Seal all edges with waterproof sealant to prevent moisture ingress.

- Proper Fastening: Use stainless steel or galvanized screws and nails to avoid rusting and staining.

- Ventilation: Ensure proper ventilation in enclosed areas to reduce moisture buildup.

- Regular Maintenance: Clean and inspect the plywood regularly, especially in marine environments, to maintain its condition.

Unveiling the Benefits of ROCPLEX Marine Plywood

ROCPLEX Marine Plywood is not just another product on the market; it is a testament to superior engineering and meticulous craftsmanship. Every sheet is designed to offer unparalleled performance, ensuring that whatever your project, it stands up to the toughest conditions with grace and resilience.

Durability Like No Other

One of the standout features of ROCPLEX Marine Plywood is its durability. Built to endure the rigors of marine environments, this plywood is resistant to the elements, including water, humidity, and temperature variations. This makes it an ideal choice for structures that require long-lasting materials.

- Rot and Decay Resistance: ROCPLEX Marine Plywood is treated to resist fungal attacks, which are common in wet environments. This treatment significantly extends the lifespan of the plywood, making it a wise investment for any marine project.

- Impact Resistance: The high-quality veneers and robust construction provide excellent resistance to physical impacts, ensuring that the plywood remains intact even under heavy loads and harsh conditions.

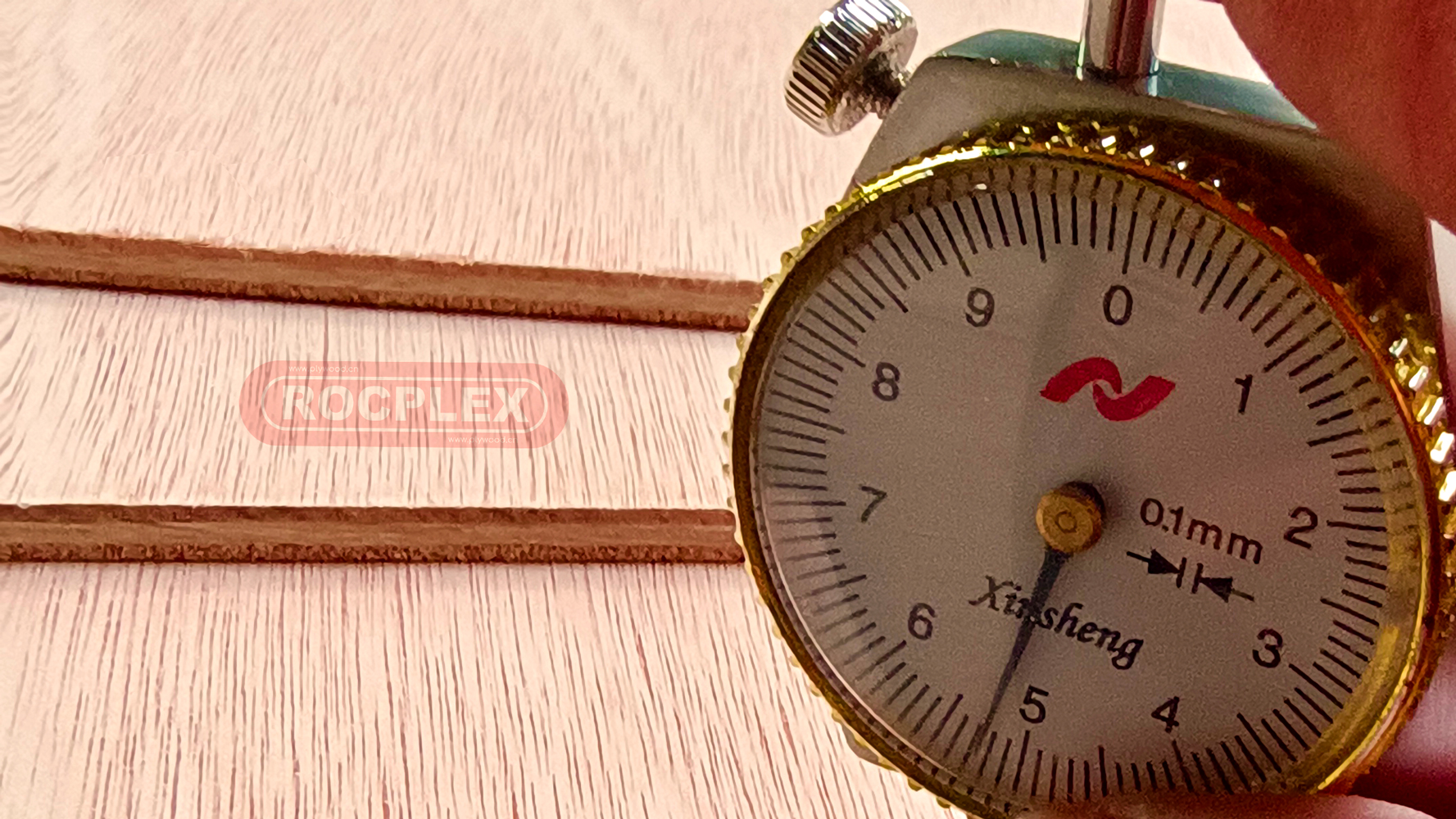

Exceptional Quality Control

At ROCPLEX, quality control is a priority. Each sheet of marine plywood undergoes rigorous testing to meet the highest standards. This ensures that every piece delivered to customers is free from defects and performs as expected in demanding environments.

- Consistent Thickness and Density: ROCPLEX ensures that each sheet has a uniform thickness and density, which is crucial for structural integrity and ease of use.

- Precision Engineering: The use of advanced machinery and skilled craftsmanship results in plywood that has a smooth finish, making it easy to work with and perfect for fine detailing.

Eco-Friendly Manufacturing

ROCPLEX is committed to sustainability. The production process of ROCPLEX Marine Plywood involves environmentally friendly practices, ensuring that the impact on the planet is minimized.

- Sustainable Sourcing: The timber used in ROCPLEX Marine Plywood is sourced from responsibly managed forests, supporting the preservation of natural ecosystems.

- Low Emission Adhesives: The adhesives used in the manufacturing process have low formaldehyde emissions, making the plywood safer for both the environment and the end users.

Versatility of Marine Plywood

ROCPLEX Marine Plywood’s versatility makes it suitable for a wide range of applications beyond marine environments. Its high performance in moist and challenging conditions makes it a favorite among builders and designers for various uses.

Flooring and Decking

For outdoor flooring and decking, ROCPLEX Marine Plywood is an excellent choice. Its resistance to moisture ensures that the flooring remains stable and intact, even when exposed to rain or humidity. It provides a solid foundation that is both durable and aesthetically pleasing.

Roofing and Cladding

Marine plywood is also ideal for roofing and cladding applications. Its ability to withstand harsh weather conditions without compromising on structural integrity makes it a reliable material for protecting buildings and structures.

Exhibition Stands and Displays

The smooth finish and easy workability of ROCPLEX Marine Plywood make it perfect for creating exhibition stands and displays. Its durability ensures that the stands can be used repeatedly, while its aesthetic appeal enhances the overall presentation.

Crafting with Confidence

Builders and craftsmen prefer ROCPLEX Marine Plywood for its ease of use and reliable performance. Whether cutting, drilling, or shaping, this plywood responds well to various tools and techniques, making it a pleasure to work with.

- Smooth Cuts: The high-quality veneers used in ROCPLEX Marine Plywood result in clean, smooth cuts, reducing the risk of splintering and ensuring a professional finish.

- Easy Fastening: Whether using nails, screws, or adhesives, ROCPLEX Marine Plywood provides a secure hold, ensuring that all joints and connections remain strong over time.

Commitment to Customer Satisfaction

ROCPLEX is dedicated to ensuring customer satisfaction by providing top-notch products and excellent service. The company’s commitment to quality and innovation ensures that every customer receives a product that meets their expectations and exceeds industry standards.

- Expert Support: ROCPLEX offers expert support to help customers choose the right plywood for their specific needs and applications. Their knowledgeable team is always ready to provide guidance and answer any questions.

- Reliable Supply Chain: With a robust supply chain, ROCPLEX ensures timely delivery of products, so projects can proceed without delays.

Product Variants and Customization

To cater to diverse needs, ROCPLEX Marine Plywood is available in various grades and thicknesses. Customers can choose the type that best suits their specific project requirements.

- Standard Grades: Available in AA, AB, and BB grades, each offering different levels of finish quality and veneer consistency.

- Custom Thicknesses: While standard thicknesses are readily available, ROCPLEX can also produce custom thicknesses upon request, ensuring that all project specifications are met.

Enhancing Marine Structures

For marine structures, using high-quality materials is crucial for ensuring safety and longevity. ROCPLEX Marine Plywood provides the perfect solution, offering both the strength and durability required to withstand the harsh marine environment.

- Boat Interiors: Ideal for creating robust and aesthetically pleasing boat interiors, ROCPLEX Marine Plywood’s smooth finish and water resistance make it perfect for cabinets, seats, and paneling.

- Hull Construction: The strength and stability of ROCPLEX Marine Plywood ensure that boat hulls are both durable and reliable, providing safety and performance on the water.

Final Thoughts on Marine Plywood

ROCPLEX Marine Plywood is a top choice for builders and designers who demand the best. Its superior water resistance, strength, and durability make it ideal for a wide range of applications, from boat building to outdoor furniture. With ROCPLEX Marine Plywood, you can be confident that your projects will stand the test of time and perform exceptionally well in any environment.

Stay tuned for more insights and detailed information about the unique features of ROCPLEX Marine Plywood and how it can elevate your construction projects to new heights.

Post time: Jun-01-2024