The Genesis of Plywood 1 2

Origins: As the plywood industry progressed, there arose a need for specialized plywood that could cater to specific requirements. ROCPLEX, always being at the forefront of innovation, saw this gap and birthed Plywood 1 2.

Research and Development: ROCPLEX commitment to excellence pushed them to invest heavily in R&D. The result? Plywood 1 2—a culmination of advanced engineering and deep understanding of customer needs.

What Makes Plywood 1 2 Unique?

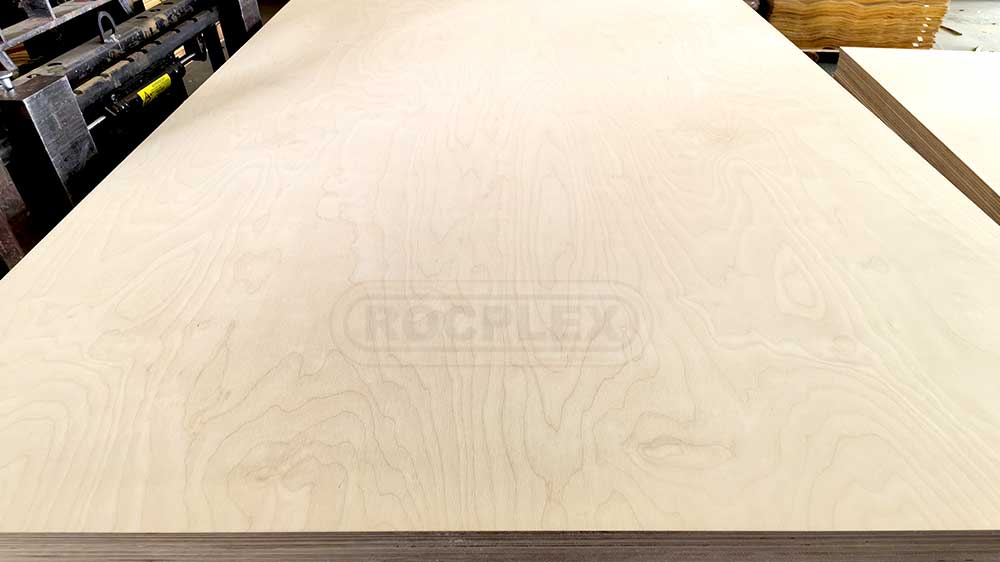

Optimized Thickness: While the market is flooded with varied plywood sizes, 12mm plywood sheets strike a balance. They’re robust enough for structural applications yet pliable for intricate designs.

Uniform Layers: Consistency is key. ROCPLEX ensures that every Plywood 1 2 sheet is uniformly pressed, guaranteeing a smooth and even surface that craftsmen love.

Eco-friendly Manufacturing: Sustainability is at the core of ROCPLEX. The brand ensures that Plywood 1 2 is produced with minimal environmental impact, aligning with global green standards.

Beyond the Basics: Dive Deeper

Aesthetic Appeal: Plywood 1 2 isn’t just about performance. Its visually pleasing grain patterns make it ideal for furniture and décor where appearance is paramount.

Adaptable to Environments: Whether it’s humid coastal regions or dry interiors, Plywood 1 2 stands resilient, thanks to its engineered properties and premium treatments.

Plywood 1 2 in Contemporary Infrastructure

Building and Construction: Plywood 1 2 12mm profile is not just a random choice. It’s optimized for strength, making it a go-to for constructors and architects. From roofing to flooring, its applications are vast and varied.

Craftsmanship and Artistry: The uniform grain of Plywood 1 2 acts as a blank canvas for artisans. Its adaptability means it’s equally suited for delicate woodwork as it is for large installations.

Industrial Use: Industries demand materials that can withstand rigorous conditions. ROCPLEX Plywood 1/2, with its robust build and resistance to external factors, is a staple in various industrial applications.

ROCPLEX Plywood 1 2 Commitment to Quality

Quality Checks: ROCPLEX understands the weight of trust customers place in their brand. Thus, every Plywood 1 2 sheet undergoes meticulous quality checks, ensuring what reaches the market is nothing short of the best.

Continuous Innovation: The introduction of Plywood 1 2 is just one chapter in ROCPLEX book of innovations. The brand consistently seeks feedback, making iterations and improvements to serve its audience better.

Feedback Loop: A two-way communication channel is maintained with clients and distributors. It’s not just about selling plywood; it’s about building relationships and ensuring that the Plywood 1 2 you get today is even better tomorrow.

Plywood 1 2: An Economic Powerhouse

Boosting Local Economies: By sourcing materials responsibly and providing employment opportunities, ROCPLEX has stimulated economic growth in areas they operate.

Global Outreach: While Plywood 1 2 has its roots in local craftsmanship, its wings spread globally. Exporting to various countries, ROCPLEX is putting Plywood 1 2 on the world map, one sheet at a time.

The Production Process of plywood 1 2

Harvesting the Best Timber: The journey of Plywood 1 2 begins in the dense forests where the finest trees are selected. ROCPLEX ensures sustainable logging, making sure the environment is as cherished as the product.

Crafting the Layers: Plywood, by definition, is layers of wood veneer pressed together. It’s the quality and treatment of these layers that set Plywood 12mm apart. Each layer undergoes precision engineering, ensuring uniform thickness and strength.

Bonding with Excellence: A good product is often more than the sum of its parts. The layers of veneer are bonded using high-quality adhesives under controlled conditions. This ensures Plywood 1 2 stands firm against external pressures and the test of time.

Plywood 1 2 Ecological Footprint

Sustainable Practices: ROCPLEX holds a strong vision of a green future. Every tree that’s used in the production of Plywood 1 2 is replaced. The brand collaborates with local communities for reforestation initiatives, ensuring a greener tomorrow.

Recyclability and Reusability: Plywood 1 2 is not just durable but also recyclable. Old and unused sheets often find their way back into the production chain, reducing waste and promoting a circular economy.

Technical Advantages of Plywood 1 2

High Load-bearing Capacity: Thanks to its 12mm profile and engineering, Plywood 1 2 boasts an impressive strength-to-weight ratio. This characteristic makes it a preferred choice in construction, where load-bearing is crucial.

Resistance to Weather: Plywood can often be vulnerable to weather conditions. However, Plywood sheet 1 2, with its specialized treatment, resists the effects of moisture, sun, and even pests.

Flexibility in Design: While Plywood 1 2 is robust, it doesn’t compromise on flexibility. This dual nature means it can be molded and used in intricate designs without the fear of it breaking or losing its shape.

Domestic Applications: More Than Just Furniture

Elegant Home Interiors: Plywood 1 2 is the backbone of many modern home designs. From stylish wall panels to bespoke furniture pieces, its versatility allows homeowners to experiment with designs that combine aesthetics with functionality.

DIY Projects: For the hobbyists and DIY enthusiasts, Plywood 1 2 is a boon. Its workability ensures that crafting bookshelves, tables, or even artistic installations is as smooth as the product itself.

Outdoor Constructions: Think beyond the interiors. Plywood 1 2, with its weather-resistant properties, is perfect for creating external structures like treehouses, garden furniture, or even patios.

Commercial and Industrial Applications

Construction Marvels: ROCPLEX Plywood 1 2 is a game-changer in the world of commercial construction. Its strength and resilience mean it’s an ideal choice for formworks, frameworks, and partitions in large structures.

Transportation: The automotive and transportation sectors value Plywood panel 1 2 for its lightweight nature. Whether it’s in caravan interiors, boat building, or even truck linings, Plywood 1 2 proves its worth.

Caring for Your Plywood 1 2

Regular Maintenance: To ensure that Plywood board 1 2 retains its beauty and functionality, regular cleaning with a damp cloth is advisable. Avoid using harsh chemicals that might damage its finish.

Protection from Extremes: Although Plywood 1 2 boasts resistance against weather, protecting it from extreme conditions prolongs its life. If used outdoors, consider applying a protective sealant.

Consult the Experts: ROCPLEX has a team of experts on standby to guide customers. Whether it’s installation advice or aftercare tips, their expertise ensures Plywood 1 2 stays pristine for years.

Post time: Sep-16-2024