Scaffold Planks: The Backbone of Safe Construction

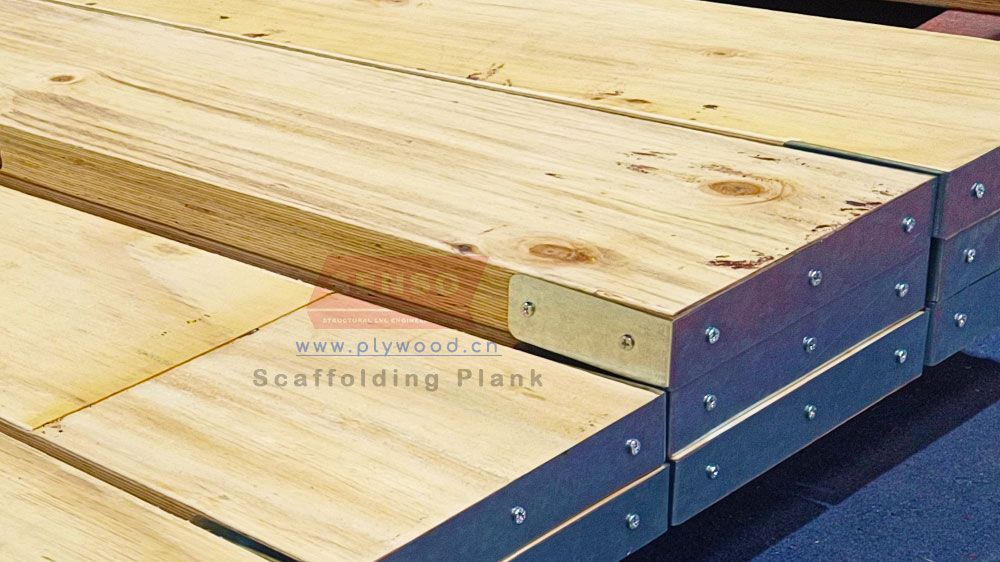

Every construction worker understands the paramount importance of safety. Scaffold planks lay the very foundation upon which professionals tread, work, and create towering structures. Their quality can’t be compromised. Enter the world of LVL (Laminated Veneer Lumber) scaffold planks, which are not just another addition to the construction palette but a revolution.

Understanding LVL Technology

LVL is a high-strength engineered wood product. It’s made by bonding together multiple layers of thin wood veneers under heat and pressure. Each layer’s grain runs parallel to the plank length, which gives it strength.

Why LVL for Scaffold Planks?

Traditional scaffold planks, though functional, come with limitations. LVL technology infuses scaffold planks with characteristics that are essential in the modern construction landscape:

Enhanced Strength

Scaffold planks made from LVL boast an impressive strength-to-weight ratio. They can bear loads that would cause other materials to falter. This strength ensures that they serve as a reliable platform for workers and materials.

Durability

These planks resist warping, twisting, and shrinking. Their structural integrity remains intact over extended periods, ensuring that rework or frequent replacements are a thing of the past.

Uniformity

Given their manufacturing process, LVL scaffold planks offer a consistent quality. There’s no need to be concerned about natural defects, such as knots or splits, which can be found in traditional wood.

Adapting to Varied Requirements

Versatility in Sizes and Thicknesses

Scaffold planks must adapt to diverse construction needs. LVL technology doesn’t just stick to a one-size-fits-all approach. Instead, these scaffold planks can be crafted in a range of sizes and thicknesses. This adaptability ensures that they fit perfectly into different scaffold systems, be it for a home renovation or a skyscraper construction.

Tailored for Tough Conditions

Work sites are not always predictable. They can be subjected to varying weather conditions, from torrential downpours to scorching sun. LVL scaffold planks stand resilient in such fluctuating environments. Their resistance to moisture and temperature variations ensures longevity and reduces the risks associated with plank degradation.

Environmental Considerations

In today’s eco-conscious world, sustainable practices in construction are not just preferred but often mandated. Here’s how LVL scaffold planks align with these green initiatives:

Sustainable Forestry

The wood veneers used in LVL are sourced from sustainably managed forests. This ensures a lower carbon footprint and promotes responsible forestry, ensuring that our forests thrive for generations to come.

Efficient Use of Timber

Traditional wood planks may require using the best parts of a tree, leading to wastage. LVL, on the other hand, utilizes more of each tree. Veneers can be derived from parts of the wood that might otherwise be discarded. This efficient use of timber resources makes LVL a more environmentally friendly choice.

Recyclability

At the end of their long life, LVL scaffold planks can be recycled. They can be repurposed or processed to produce other engineered wood products, ensuring minimal waste and a continued life for the wood components.

Safety: A Non-Negotiable Priority

Meeting and Exceeding Standards

LVL scaffold planks aren’t just about innovations and sustainability; they are rigorously tested to meet stringent safety standards. These planks often exceed the minimum requirements set by industry bodies, providing an added layer of assurance to construction teams.

Reduced On-site Accidents

The predictable strength and uniformity of LVL scaffold planks translate to reduced risks. With traditional wood, inconsistencies might lead to weak points in the scaffold, resulting in unfortunate accidents. LVL’s consistent quality helps in significantly reducing such on-site mishaps.

Embracing Technological Advancements

In an era where technology drives most industries forward, the construction domain is no exception. LVL scaffold planks are a testament to how technological advancements can revolutionize traditional materials.

Precision in Manufacturing

One of the most commendable aspects of LVL scaffold planks is the precision with which they’re manufactured. Advanced machinery and technology ensure that each plank is crafted to exact dimensions, eliminating the inconsistencies seen in natural wood. This precise production guarantees a uniform product, reducing the chance of errors during construction.

Enhancements through Research

Continuous research into improving the properties of LVL scaffold planks has led to enhancements in their strength, durability, and resistance to external elements. This dedication to research and development means that LVL scaffold planks are not just keeping up with industry standards but often setting them.

Economic Advantages

While the initial cost of LVL scaffold planks might be higher than traditional wood options, their benefits result in long-term savings for contractors and construction companies.

Reduced Replacement Costs

Given their durability and resistance to environmental factors, LVL scaffold planks don’t need frequent replacements. This durability translates to savings in the long run, as the frequency of purchasing new planks reduces significantly.

Fewer Maintenance Expenses

Maintenance is a recurring expense that can strain a construction project’s budget. Thanks to the protective layers and treatments, LVL scaffold planks demand less maintenance, further reducing costs.

Increased Work Efficiency

Time is money in the construction world. LVL scaffold planks, being consistent in quality and free from defects, reduce the time spent inspecting and sorting materials. This increased efficiency accelerates the construction process, leading to faster project completions and reduced labor costs.

Customer Testimonials: A World of Difference

Hearing directly from those who’ve incorporated LVL scaffold planks into their projects can shed light on their real-world advantages.

James Martinez, a veteran contractor, shares: ”Switching to LVL scaffold planks was a game-changer. The consistency in quality meant fewer hiccups during construction, and the durability has led to noticeable cost savings over multiple projects.”

Anna Greene, a site manager, recounts: ”Safety is paramount for us. The predictable strength of LVL planks offers peace of mind, knowing that we’re providing a safer environment for our workers.”

Addressing Environmental Concerns

In today’s ecologically conscious era, the construction industry’s environmental footprint is under constant scrutiny. Thankfully, LVL scaffold planks align well with green construction initiatives, setting an example for sustainable construction materials.

Sustainable Forestry Practices

The production of LVL scaffold planks involves timber sourced from managed forests. These forests are maintained with practices that ensure reforestation, providing a renewable resource for the construction industry. Such a system ensures a consistent supply without endangering natural habitats or reducing the planet’s green cover.

Waste Reduction in Production

Traditional wood processing can result in significant waste, given the inconsistencies in raw materials. However, LVL manufacturing leverages almost every part of the log. Advanced machinery processes the wood to produce consistent planks, minimizing waste and making the most of the resource.

Longevity Equals Less Waste

The durability of LVL scaffold planks means they last longer than many conventional alternatives. Their extended lifespan leads to reduced frequency of replacements, meaning fewer resources are used over time. This longevity not only serves economic interests but also reduces waste, further underscoring their environmental benefits.

Aesthetic Appeal: Not Just Functional

Beyond their functional advantages, LVL scaffold planks have a unique aesthetic that many find appealing. Their manufacturing process results in a visually consistent grain pattern, providing a modern and sleek look that resonates with current architectural trends.

Versatility in Design

The uniformity of LVL scaffold planks allows architects and designers to predict how they’ll appear in finished structures. This predictability provides greater control over the final aesthetic, leading to visually pleasing results that can be tailored to fit a variety of design visions.

Coloring and Finishing

LVL scaffold planks are also versatile when it comes to finishing. They can be stained, painted, or sealed to achieve a wide range of looks, from rustic to contemporary. This adaptability ensures that they can seamlessly fit into any design scheme, making them a favored choice among designers.

Safety First: Ensuring Peace of Mind

The construction industry is rife with hazards, and ensuring worker safety is paramount. LVL scaffold planks offer advantages in this realm too, emerging as a safer alternative to many traditional materials.

Predictable Load-bearing Capacities

Thanks to the consistent manufacturing processes, LVL scaffold planks boast predictable load-bearing capacities. Workers and site managers can be confident in the planks’ ability to handle designated loads, reducing risks associated with overloading or material failures.

Reduced Risk of Splintering

Traditional wood can splinter, posing a risk to workers. The refined manufacturing process of LVL reduces the likelihood of splinters, ensuring a safer working environment and reducing the chance of injuries on site.

An Investment Worth Making

Every construction project requires careful consideration of costs. While initial expenses are essential, it’s the long-term value that often dictates the best investment. LVL scaffold planks, with their myriad of benefits, present a compelling case as a sound financial decision.

Cost Efficiency Over Time

While the initial cost of LVL scaffold planks might be higher than traditional wood, their prolonged lifespan ensures cost savings in the long run. The reduced need for replacements means fewer purchases over the life of a project. When you consider the costs associated with frequent replacements and the potential downtime during replacements, the long-term savings become evident.

Maintenance Savings

Maintenance can be a significant drain on project budgets. The resilience of LVL scaffold planks to environmental factors means they require less maintenance than many traditional alternatives. Fewer treatments and repairs translate to more savings, making them an economically savvy choice for projects.

Increased Productivity

LVL scaffold planks are not just about savings; they can also contribute to revenue. Their predictable nature, in terms of strength and durability, can lead to faster construction times. Faster construction can mean earlier project completion, allowing businesses to realize their return on investment sooner.

Navigating the Regulatory Landscape

Regulations in the construction industry are stringent, ensuring safety and environmental preservation. LVL scaffold planks, being a product of innovative processes, align well with these regulations.

Meeting Industry Standards

Thanks to rigorous testing and quality controls during manufacturing, LVL scaffold planks consistently meet or exceed industry standards. Their reliability ensures that projects utilizing them are less likely to face regulatory hiccups or delays.

Eco-friendly Credentials

Many regions are now enforcing green building codes. The sustainable nature of LVL scaffold planks, from sourcing to production, makes them a suitable choice for projects aiming to achieve eco-friendly certifications or adhere to strict environmental guidelines.

Embracing Future Innovations

The world of construction is continuously evolving, with new materials and techniques emerging regularly. LVL scaffold planks, born from innovation, are well poised to adapt to future advancements.

Potential for Further Refinement

As technology progresses, there’s potential for even more refined and efficient production of LVL scaffold planks. This evolution will likely result in even more durable, consistent, and environmentally friendly products.

Collaboration with New Technologies

The predictability and uniformity of LVL scaffold planks make them ideal candidates for integration with emerging construction technologies, such as advanced joining techniques or automation in construction.

Scaffold Planks Reinvented with LVL

LVL scaffold planks represent a harmonious blend of tradition and innovation in the construction industry. Their multiple advantages, ranging from durability and safety to environmental benefits, make them an indispensable asset for modern construction projects. As the industry marches forward, embracing change and innovation, LVL scaffold planks stand as a testament to what can be achieved when tradition meets forward-thinking. For construction professionals and businesses, investing in such materials is not just a nod to the present but a wise gaze into the future.

Post time: Oct-29-2023