What is Structural Plywood?

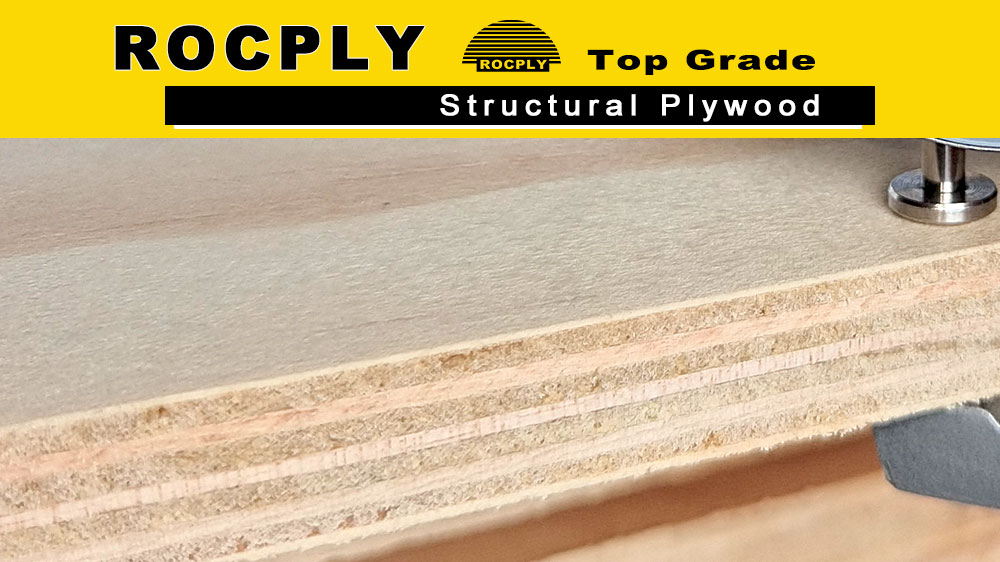

Structural plywood is an engineered wood product designed for use in construction. It is manufactured by gluing together multiple layers of wood veneers, with each layer’s grain direction perpendicular to the adjacent one. This cross-grain structure enhances the strength and stability of the plywood, making it suitable for structural applications.

The primary use of structural plywood is in building and construction projects where load-bearing and strength are critical. It is commonly used for flooring, wall sheathing, roofing, and other structural components. The durability and strength of structural plywood come from the high-quality veneers and adhesives used in its manufacturing process.

Structural plywood is manufactured to meet specific standards, ensuring it can withstand the loads and stresses encountered in construction. It is often graded based on its performance in these applications, with higher grades offering greater strength and reliability. The result is a versatile and dependable material that forms the backbone of many building projects.

The Versatility of Structural Plywood in Construction

Structural plywood is highly versatile, making it a valuable material for various construction applications.

Durability and Strength

Structural plywood is renowned for its durability and strength. Its cross-grain construction and high-quality adhesives ensure it can withstand heavy loads and stresses, making it ideal for structural applications.

Load-Bearing Capacity

One of the key features of structural plywood is its load-bearing capacity. It can support significant weights, making it suitable for use in flooring, roofing, and wall sheathing. This capacity ensures the stability and integrity of the structures it supports.

Moisture Resistance

Structural plywood often includes treatments to enhance its moisture resistance. This feature is crucial for applications where the plywood may be exposed to damp conditions, such as in roofing or exterior wall sheathing. The moisture resistance prevents swelling, warping, and deterioration over time.

Versatile Applications

The versatility of structural plywood allows it to be used in various applications. From residential to commercial construction, it is used in flooring, walls, roofs, and even in specialized applications like formwork and scaffolding. Its ability to perform in different conditions and environments makes it a go-to material for builders.

Key Applications of Structural Plywood

Structural plywood is used in a wide range of applications, providing essential support and strength to various construction projects.

Flooring

In flooring applications, structural plywood offers a stable and durable base. It is used as a subfloor beneath finished flooring materials, providing the necessary support and ensuring a level surface.

Wall Sheathing

Structural plywood is commonly used for wall sheathing, providing a strong and stable layer that supports exterior cladding and insulation. It enhances the overall strength of the building’s structure, ensuring it can withstand various loads and stresses.

Roofing

For roofing applications, structural plywood serves as a reliable underlayment for roofing materials. Its strength and moisture resistance make it ideal for supporting shingles, tiles, and other roofing materials, ensuring the roof’s durability and integrity.

Formwork

In concrete construction, structural plywood is used to create formwork molds. These molds hold the wet concrete in place until it sets and cures, providing the necessary shape and support for concrete structures.

Scaffolding

Structural plywood is also used in scaffolding applications, providing a stable platform for workers and materials. Its strength and durability ensure it can support significant weights, enhancing safety and efficiency on construction sites.

Advantages of Using Structural Plywood

The use of structural plywood offers several advantages in construction projects, ensuring strength, stability, and durability.

High Strength-to-Weight Ratio

Structural plywood has a high strength-to-weight ratio, making it strong yet lightweight. This property makes it easier to handle and install, reducing labor costs and improving efficiency on construction sites.

Cost-Effective

Structural plywood is a cost-effective material, offering excellent performance at a reasonable price. Its durability and load-bearing capacity ensure long-term reliability, reducing the need for frequent repairs and replacements.

Easy to Work With

Structural plywood is easy to cut, shape, and fasten, making it a versatile material for various construction applications. Its workability allows for precise installations and adjustments, ensuring a perfect fit in any project.

Environmentally Friendly

Many manufacturers produce structural plywood using sustainable forestry practices. This eco-friendly approach ensures that the material is not only durable but also responsible, contributing to the preservation of natural resources.

Manufacturing Process of Structural Plywood

Structural plywood is manufactured using a meticulous process to ensure its strength and durability.

Selection of Raw Materials

The process begins with selecting high-quality wood veneers. These veneers are chosen for their strength, stability, and resistance to defects, ensuring the final product’s reliability.

Cross-Grain Construction

The veneers are arranged in a cross-grain pattern, where each layer’s grain runs perpendicular to the next. This construction method enhances the plywood’s strength and stability, preventing warping and splitting.

Adhesive Application

High-quality adhesives are applied between the veneer layers. These adhesives are critical for bonding the layers together and ensuring the plywood’s structural integrity. Phenolic and other synthetic resins are commonly used due to their excellent bonding and water resistance properties.

Pressing and Curing

The veneers with adhesive are pressed together under high pressure and heat. This process bonds the layers firmly, ensuring the plywood’s strength and durability. The curing process solidifies the adhesive, making the plywood resistant to moisture and environmental factors.

Quality Control

After pressing and curing, the plywood undergoes rigorous quality control tests to ensure it meets the required standards. These tests include checking for defects, measuring thickness and strength, and assessing the adhesive bonds.

Quality Standards for Structural Plywood

Structural plywood is manufactured to meet specific quality standards, ensuring its reliability and performance in construction applications.

APA Rated Sheathing

The American Plywood Association (APA) provides ratings for structural plywood, indicating its suitability for various applications. APA-rated sheathing is tested for strength, stiffness, and durability, ensuring it meets the requirements for structural use.

PS 1-09 and PS 2-10 Standards

In the United States, structural plywood must meet the PS 1-09 and PS 2-10 standards. These standards specify the requirements for wood species, adhesive types, and construction methods, ensuring the plywood’s performance in structural applications.

AS/NZS 2269 Standard

In Australia and New Zealand, the AS/NZS 2269 standard specifies the requirements for structural plywood. This standard ensures that the plywood meets the necessary strength and durability criteria for construction projects in these regions.

EN 13986 Standard

In Europe, the EN 13986 standard outlines the requirements for wood-based panels, including structural plywood. This standard ensures that the plywood meets the necessary performance criteria for structural applications in European construction projects.

Choosing the Right Structural Plywood for Your Project

Selecting the appropriate structural plywood for your project involves considering several factors to ensure optimal performance and durability.

Grade of Plywood

Structural plywood is available in different grades, indicating the quality and appearance of the veneers used. Common grades include A-B, B-B, and C-D. Higher grades offer better strength and appearance, suitable for visible or load-bearing applications.

Thickness and Size

The thickness and size of the plywood sheets are important considerations. Thicker plywood offers more strength and stability, while thinner sheets are lighter and easier to handle. Common thicknesses range from 6mm to 25mm, and standard sizes include 4×8 feet and 5×10 feet.

Source and Certification

Choosing plywood from a reputable manufacturer with appropriate certifications ensures quality and performance. Look for products that meet recognized standards such as APA, PS 1-09, PS 2-10, or AS/NZS 2269.

Intended Use

Consider the specific requirements of your project when selecting structural plywood. For load-bearing applications, high-grade, thick plywood with excellent strength is essential. For non-structural uses, lower grades may suffice if they still meet the necessary durability criteria.

Maintaining Structural Plywood

Proper maintenance of structural plywood is crucial for extending its lifespan and ensuring its performance in construction applications.

Regular Inspections

Conduct regular inspections of structural plywood structures to check for signs of damage, rot, or delamination. Early detection of issues allows for timely repairs, preventing further deterioration.

Protective Coatings

Applying protective coatings, such as paint or sealant, enhances the water resistance of the plywood. These coatings create a barrier against moisture and environmental factors, extending the plywood’s lifespan.

Proper Storage

Store structural plywood in a dry, well-ventilated area when not in use. Avoid exposing it to direct sunlight or moisture to prevent warping and deterioration. If storing for an extended period, stack the plywood flat with adequate support to maintain its shape.

Regular Cleaning

Clean structural plywood surfaces regularly to remove dirt, dust, and other contaminants that can accelerate wear and tear. Use mild soap and water, avoiding harsh chemicals that could damage the plywood or its protective coatings.

FAQs

Q: What makes structural plywood different from regular plywood?

A: Structural plywood is designed for load-bearing applications, offering greater strength and stability compared to regular plywood. It meets specific standards for construction use.

Q: Can structural plywood be used for roofing?

A: Yes, structural plywood is ideal for roofing applications. Its strength and moisture resistance make it suitable for supporting roofing materials and withstanding environmental conditions.

Q: How long does structural plywood last?

A: Structural plywood is designed to be long-lasting, especially when properly maintained. With regular inspections and protective treatments, it can last many years.

Q: Is structural plywood environmentally friendly?

A: Many manufacturers produce structural plywood using sustainable practices, making it an eco-friendly choice for construction projects.

Q: Can structural plywood be painted or stained?

A: Yes, structural plywood can be painted or stained to match the desired aesthetic of a project. Its surface accepts finishes well, enhancing its appearance and protection.

Q: What are the common uses of structural plywood?

A: Structural plywood is commonly used in flooring, wall sheathing, roofing, formwork, and scaffolding due to its strength and durability.

Post time: Sep-01-2024