Wood concrete form, a groundbreaking innovation in the construction industry, represents a significant shift from traditional building methods. This technology utilizes high-quality timber, often phenolic plywood or shuttering ply, to create molds for concrete structures. The versatility and strength of wood concrete forms have made them a preferred choice for various construction projects, offering efficiency and sustainability.

What Timber is Used to Form Concrete?

The Essence of Timber in Concrete Formation

Timber has long been a fundamental component in construction, but its role in forming concrete is particularly noteworthy. Wood concrete forms are typically made from robust materials like phenolic plywood or shuttering plywood. These materials are chosen for their durability, resistance to moisture, and ability to withstand the pressure of wet concrete. The timber used in these forms is treated to ensure longevity and reusability, making it an eco-friendly option in the construction sector.

Advantages of Timber in Concrete Forming

The use of timber in concrete forming brings several advantages. Its natural flexibility allows for the creation of diverse shapes and sizes, catering to unique architectural designs. Moreover, timber forms provide excellent thermal insulation, enhancing the curing process of concrete. The ease of assembly and disassembly of wood forms also contributes to reduced labor costs and time efficiency in construction projects.

Why Use Wood Instead of Concrete?

Sustainability and Environmental Impact

Choosing wood over concrete for formwork is a decision that significantly benefits the environment. Wood is a renewable resource, and its use in construction reduces the carbon footprint. The production process of wood forms is less energy-intensive compared to metal forms, further contributing to environmental sustainability.

Cost-Effectiveness and Efficiency

Wood concrete forms are not only environmentally friendly but also cost-effective. They are lighter than metal forms, reducing transportation and handling costs. The ease of customization and adaptability of wood forms to various designs also makes them a more efficient choice for complex construction projects.

How Strong is Timber Compared to Concrete?

Assessing the Strength and Durability

When it comes to strength, timber used in concrete forms is remarkably resilient. Phenolic plywood and shuttering plywood, commonly used in these forms, are engineered to withstand significant weight and pressure. These materials undergo treatment processes to enhance their durability and resistance to environmental factors, ensuring they maintain structural integrity throughout the construction process.

Timber’s Role in Supporting Concrete Structures

While timber may not possess the same inherent strength as concrete, its role in supporting and shaping concrete structures is crucial. The strength of timber in this context lies in its ability to hold the concrete in place as it sets, ensuring the desired shape and structural integrity of the final construction. The synergy between timber and concrete in formwork demonstrates the unique strengths of each material, working together to create robust and lasting structures.

Enhancing Construction with Phenolic Plywood and Shuttering Ply

The Role of Phenolic Plywood in Modern Construction

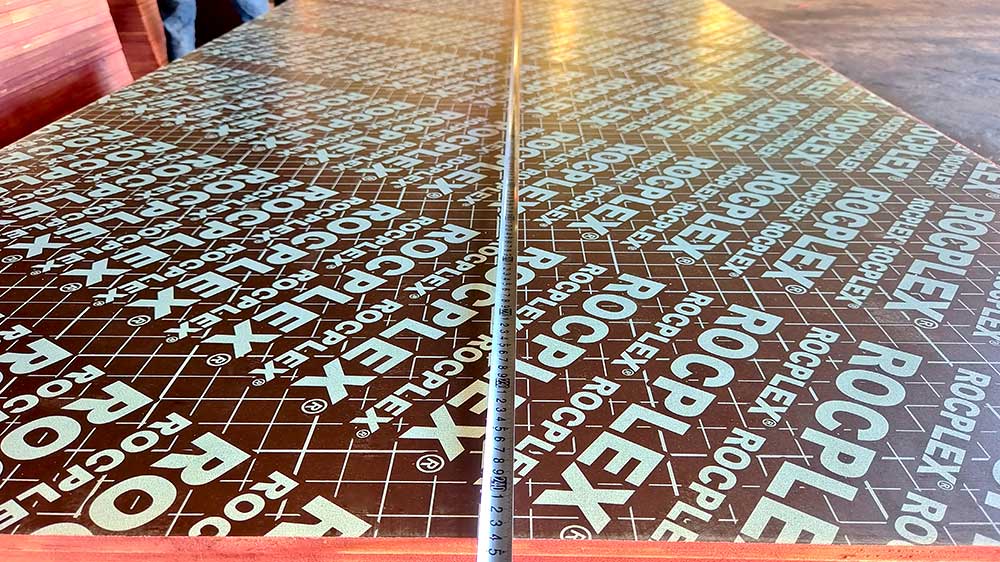

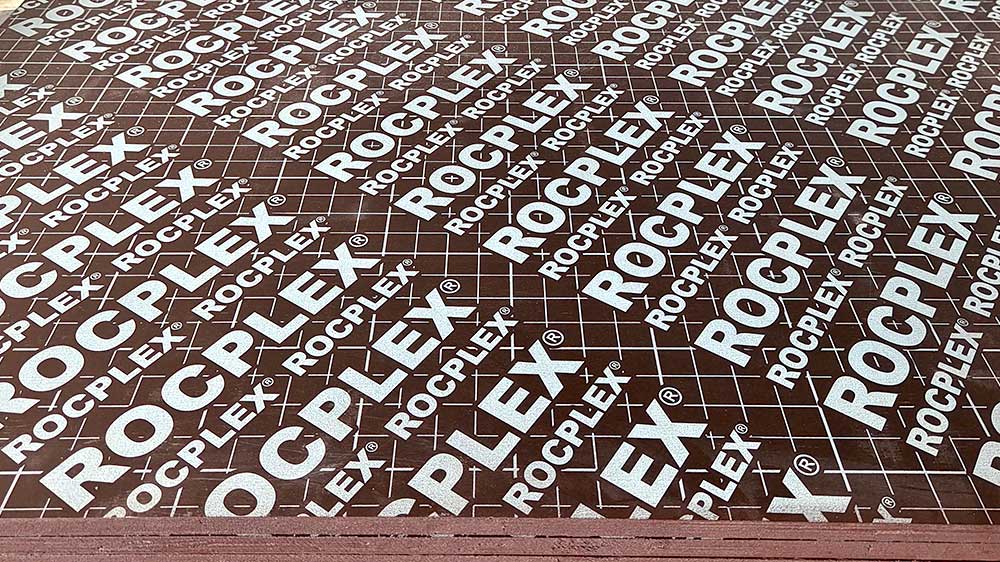

Phenolic plywood, a synonym for wood concrete form, plays a pivotal role in modern construction. This material is renowned for its exceptional durability and moisture resistance, making it ideal for concrete formwork. The phenolic resin coating ensures that the plywood can withstand prolonged exposure to water and harsh chemicals, a common scenario in concrete construction. Its smooth surface also guarantees a flawless finish on the concrete, reducing the need for additional plastering or finishing work.

Shuttering Plywood: A Game-Changer in Formwork

Similarly, shuttering plywood has revolutionized the way concrete forms are made. This type of plywood is specifically designed for shuttering or molding concrete. It is robust, withstanding the immense pressure exerted by wet concrete, and it ensures that the form remains intact and in shape during the curing process. The use of shuttering plywood not only enhances the structural integrity of the concrete but also contributes to the aesthetic quality of the finished structure.

The Evolution of Concrete Form Boards

From Traditional to Advanced Formwork Solutions

The evolution of concrete form boards is a testament to the advancements in construction technology. Traditional formwork solutions often involved the use of plain timber, which, while effective, had limitations in terms of durability and versatility. The introduction of engineered products like phenolic plywood and shuttering plywood has provided builders with more reliable, efficient, and versatile formwork options. These materials have enabled the construction of more complex and intricate architectural designs that were previously challenging to achieve.

Impact on Construction Efficiency and Safety

The use of advanced concrete form boards has significantly impacted construction efficiency and safety. These materials are lighter and easier to handle than traditional metal forms, reducing the risk of injuries on site. Their ease of installation and dismantling not only speeds up the construction process but also reduces labor costs. Furthermore, the reusability of these materials aligns with sustainable construction practices, minimizing waste and promoting environmental responsibility.

Future Trends in Wood Concrete Form Technology

Innovations and Technological Advancements

The future of wood concrete form technology is bright, with ongoing innovations and technological advancements. Researchers and manufacturers are continuously exploring ways to enhance the properties of materials like phenolic plywood and shuttering plywood. Developments in treatments and coatings are aimed at increasing durability, resistance to environmental factors, and overall performance of these materials in challenging construction scenarios.

Sustainable Practices and Eco-Friendly Solutions

Sustainability remains a key focus in the evolution of wood concrete form technology. The construction industry is increasingly leaning towards eco-friendly solutions, and wood concrete forms are at the forefront of this shift. The use of sustainably sourced timber, combined with advancements in recycling and reusability, positions wood concrete forms as a responsible choice for environmentally conscious construction projects.

The Environmental Impact of Wood Concrete Forms

Balancing Construction with Ecological Concerns

In the realm of construction, the environmental impact of materials used is a critical consideration. Wood concrete forms, including phenolic plywood and shuttering plywood, offer a more ecologically sound alternative to traditional materials. These wood-based products are derived from renewable resources, presenting a smaller carbon footprint compared to their metal or plastic counterparts. Additionally, the ability to reuse these forms multiple times before recycling further underscores their environmental friendliness.

Reducing Carbon Emissions in Construction

The production and utilization of wood concrete forms contribute to reduced carbon emissions in the construction industry. Unlike the manufacturing of steel or aluminum forms, which are energy-intensive and emit significant levels of carbon dioxide, the processing of wood for concrete forms is less demanding in terms of energy consumption. This aspect not only aligns with global efforts to combat climate change but also positions wood concrete forms as a sustainable choice for future construction endeavors.

The Economic Aspect of Wood Concrete Forms

Cost-Effectiveness in the Long Run

From an economic standpoint, wood concrete forms, including phenolic plywood and shuttering plywood, offer substantial cost benefits. Their initial purchase cost might be higher than traditional forms, but their durability and reusability translate into long-term savings. The reduced need for repairs or replacements, coupled with their ease of handling and installation, results in lower overall project costs. This economic efficiency makes wood concrete forms an attractive option for both large-scale and smaller construction projects.

Impact on the Global Construction Market

The growing preference for wood concrete forms has a significant impact on the global construction market. As more companies and contractors adopt these materials, there’s a noticeable shift towards more sustainable and cost-effective building practices. This trend not only stimulates innovation in the production of wood-based formwork but also encourages the development of new construction techniques that maximize the benefits of these materials.

Future Prospects and Challenges

Embracing Technological Integration

Looking ahead, the integration of technology with wood concrete form systems presents exciting prospects. Innovations such as digitally fabricated forms and smart monitoring systems could further enhance the efficiency and precision of construction processes. These technological advancements would not only streamline construction but also open up new possibilities in architectural design and engineering.

Addressing Challenges and Limitations

Despite the numerous advantages, wood concrete forms face challenges, particularly in terms of perception and market penetration. Overcoming the traditional preference for metal or plastic forms requires continued education and demonstration of the benefits of wood-based formwork. Additionally, addressing any limitations in terms of load-bearing capacity or specific environmental conditions remains crucial for wider adoption in the industry.

The Future is Formed in Wood

Wood concrete forms, encompassing phenolic plywood, concrete form boards, shuttering ply, and shuttering plywood, represent a significant advancement in construction technology. Their impact extends beyond mere functionality, offering environmental benefits, economic advantages, and the potential for future technological integration. As the construction industry continues to evolve, the role of wood concrete forms in shaping sustainable, efficient, and innovative building practices is undeniable. The future of construction, it seems, is indeed formed in wood.

Post time: Feb-13-2024