Products

-

Formply F14 1800 x 1200 x 17mm Formwork Plywood AS 6669 Certified

ROCPLY formply F14 1800 x 1200 x 17mm formwork plywood is a high quality construction formwork use plywood special produce for Australia and New Zealand.

ROCPLY edges are sealed with 3 times water-dispersible acrylic paint.

Find benchmark and certmark formply manufacturer, contact us ROCPLEX. -

Formply F14 2400 x 1200 x 17mm Formwork Plywood AS 6669 Certified

ROCPLY formply F14 2400 x 1200 x 17mm formwork plywood is a high quality construction formwork use plywood special produce for Australia and New Zealand.

ROCPLY edges are sealed with 3 times water-dispersible acrylic paint.

Find benchmark and certmark formply manufacturer, contact us ROCPLEX. -

Formply F22 1800 x 1200 x 17mm Formwork Plywood AS 6669 Certified

ROCPLY formply F22 1800 x 1200 x 17mm formwork plywood is a high quality construction formwork use plywood special produce for Australia and New Zealand.

ROCPLY edges are sealed with 3 times water-dispersible acrylic paint.

Find benchmark and certmark formply manufacturer, contact us ROCPLEX. -

Formply F22 2400 x 1200 x 17mm Formwork Plywood AS 6669 Certified

ROCPLY formply F22 2400 x 1200 x 17mm formwork plywood is a high quality construction formwork use plywood special produce for Australia and New Zealand.

ROCPLY edges are sealed with 3 times water-dispersible acrylic paint.

Find benchmark and certmark formply manufacturer, contact us ROCPLEX. -

Formply F27 1800 x 1200 x 17mm Formwork Plywood AS 6669 Certified

Formply F27, a product of ROCPLY, stands as a benchmark in the construction plywood sector. Known for its exceptional strength and durability, Formply F27 is the ideal choice for demanding construction environments. This high-grade formwork solution offers versatility and reliability, making it a favorite among professionals. Choose Formply F27 for all your structural plywood needs.

-

Formply F27 2400 x 1200 x 17mm Formwork Plywood AS 6669 Certified

Formply F27 by ROCPLY – a game-changer in construction formwork. Offering unmatched durability and superior finishing capabilities, Formply F27 is ideal for a wide range of applications, ensuring quality and efficiency on site. This high-density phenolic overlay formwork, designed for fixed applications, achieves a class 2 finish with proper care.

-

Luxury Vinyl Flooring – LVT Flooring

Revolutionize your living space with ROCPLEX Luxury Vinyl Flooring. Combining durability with high-end aesthetics, our vinyl flooring offers the best of both worlds. Ideal for modern homes and businesses, ROCPLEX makes luxury affordable.

-

SPC Flooring – Vinyl Flooring

Step into a world of quality and elegance with ROCPLEX Vinyl SPC Flooring. Engineered with advanced technology, this flooring solution offers unmatched durability, water resistance, and style. Whether it’s a bustling home or a busy commercial space, ROCPLEX has got you covered.

-

X-PLY Yellow Formwork Panel

The X-PLY Yellow Formwork Panel is a revolutionary breakthrough in the construction sector. Crafted with precision and unparalleled durability, this panel offers enhanced rigidity and stability, making it superior to traditional formwork materials. Each X-PLY Yellow Formwork Panel undergoes rigorous quality checks, ensuring it stands up to the demanding challenges of construction sites. With its sleek yellow finish, it not only provides structural integrity but also adds an aesthetic touch to any project. Choose the X-PLY for a blend of strength and style.

-

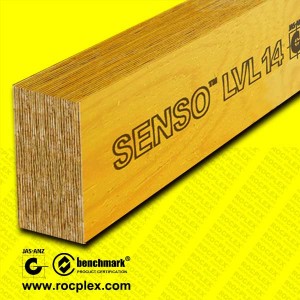

Structural LVL

ROCPLEX – SENSO Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in structural applications to carry heavy loads with minimum weight.

-

Melamine Plywood Board 2440*1220*19mm ( Common: 3/4″ x 8′ x 4′. Melamine Faced Plywood Panel )

ROCPLEX Melamine Plywood board 19mm is typically a high-quality Melamine plywood product coming in 4′ x 8′ double sided or one side melamine cover in thicknesses ranging from ⅛” to 1″.

Since 2010, ROCPLEX has started to develop and produce melamine boards. 12 years of OEM service mature experience for China TOP brands has made ROCPLEX’s melamine board more stable in quality and more advantageous in price.

ROCPLEX’s own brand also enjoys a high reputation in China for its high quality and low price.

The melamine board of ROCPLEX covers five categories: Melamine MDF, Melamine plywood, Melamine block board, Melamine chipboard and Melamine slotted board.

Tens of thousands of primary colors and patterns can be selected.

ROCPLEX willing to develop with you in melamine boards. -

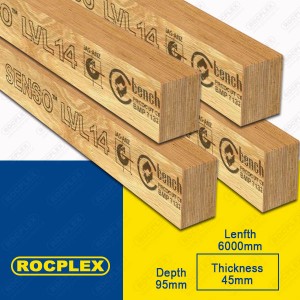

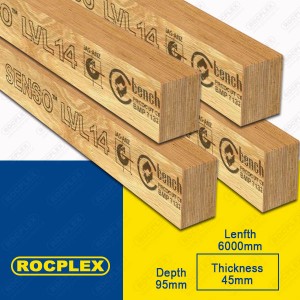

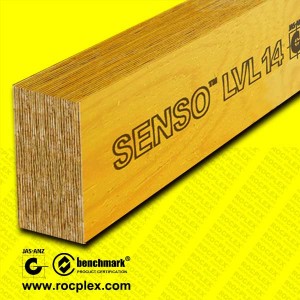

SENSO Frame 90 X 45mm F17 LVL H2S Treated Structural LVL Engineered Wood Beams E14

ROCPLEX – SENSO 90X45 Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in

structural applications to carry heavy loads with minimum weight. -

SENSO Frame 120 X 45mm F17 LVL H2S Treated Structural LVL Engineered Wood Beams E14

ROCPLEX – SENSO 120X45 E14 Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in

structural applications to carry heavy loads with minimum weight. -

SENSO Frame 130 X 45mm F17 LVL H2S Treated Structural LVL Engineered Wood Beams E14

ROCPLEX – SENSO 130X45 E14 Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in

structural applications to carry heavy loads with minimum weight. -

SENSO Frame 140 X 45mm F17 LVL H2S Treated Structural LVL Engineered Wood Beams E14

ROCPLEX – SENSO 140X45 E14 Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in

structural applications to carry heavy loads with minimum weight. -

SENSO Frame 150 X 45mm F17 LVL H2S Treated Structural LVL Engineered Wood Beams E14

ROCPLEX – SENSO 150X45 E14 Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in

structural applications to carry heavy loads with minimum weight. -

SENSO Frame 170 X 45mm F17 LVL H2S Treated Structural LVL Engineered Wood Beams E14

ROCPLEX – SENSO 170X45 E14 Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in

structural applications to carry heavy loads with minimum weight. -

SENSO Frame 190 X 45mm F17 LVL H2S Treated Structural LVL Engineered Wood Beams E14

ROCPLEX – SENSO 190X45 E14 Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in

structural applications to carry heavy loads with minimum weight. -

SENSO Frame 200 X 45mm F17 LVL H2S Treated Structural LVL Engineered Wood Beams E14

ROCPLEX – SENSO 200X45 E14 Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in

structural applications to carry heavy loads with minimum weight. -

SENSO Frame 240 X 45mm F17 LVL H2S Treated Structural LVL Engineered Wood Beams E14

ROCPLEX – SENSO 240X45 E14 Structural LVL Engineered Wood A high performance more sustainable alternative to lumber, ROCPLEX’s Laminated Veneer Lumber (LVL) beams, headers and columns are used in

structural applications to carry heavy loads with minimum weight.