Professional China Shuttering In Building Construction - Plastic Plywood – ROC

Professional China Shuttering In Building Construction - Plastic Plywood – ROC Detail:

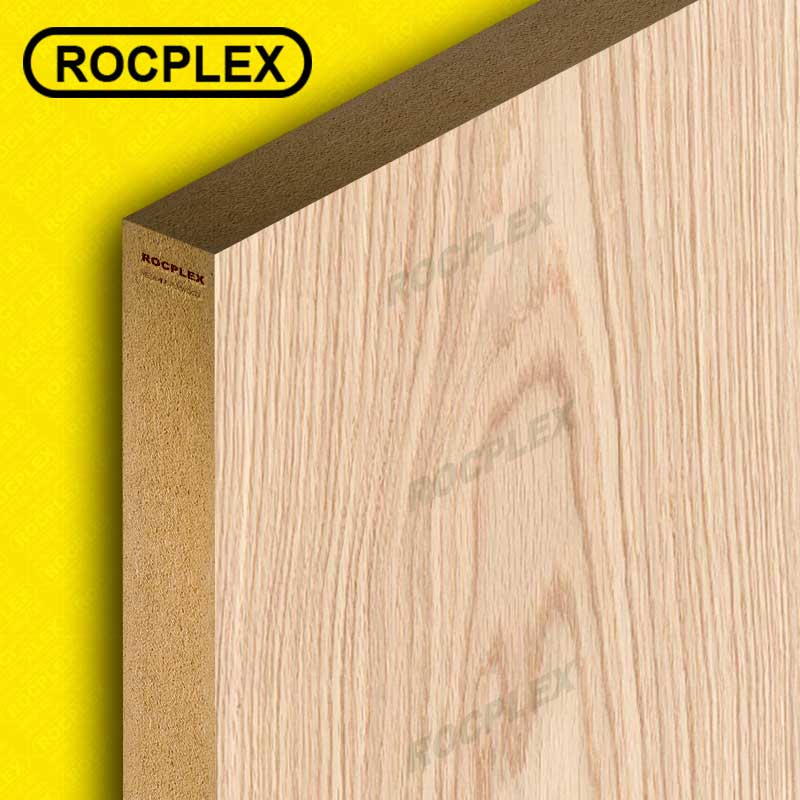

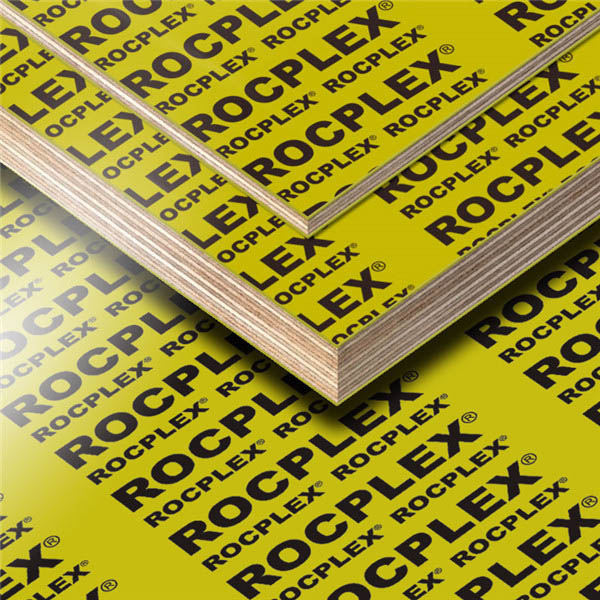

ROCPLEX Plastic plywood is a high-quality construction use plywood covered with 1.0mm plastic that turns into a protective plastic during production. Edges are sealed with water-dispersible acrylic paint.

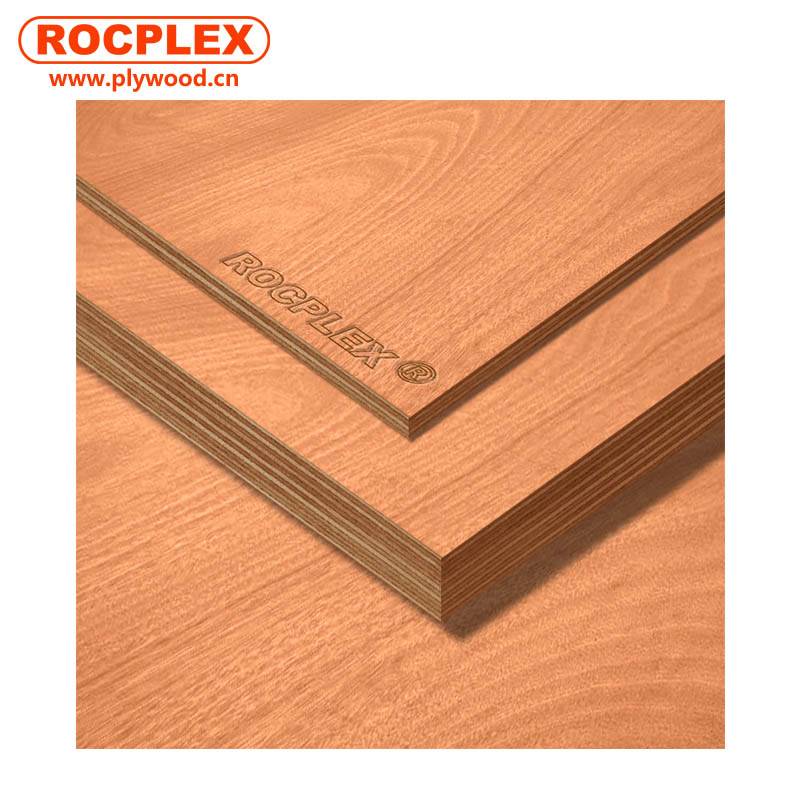

Plastic Plywood is an engineered plywood with high quality and applicability, it is widely used for House building, Road Construction, Big Concrete Projects, bridge beams,etc.

ROCPLEX PPE plastic plywood covered with polypropylene coating both sides of 1.6 mm thick.

The coating completely reduces the plastic surface absorption of the humidity of the formwork board.

Properties of wood compared to plywood conventional edge protection: Two coats of acrylic paint waterproof.

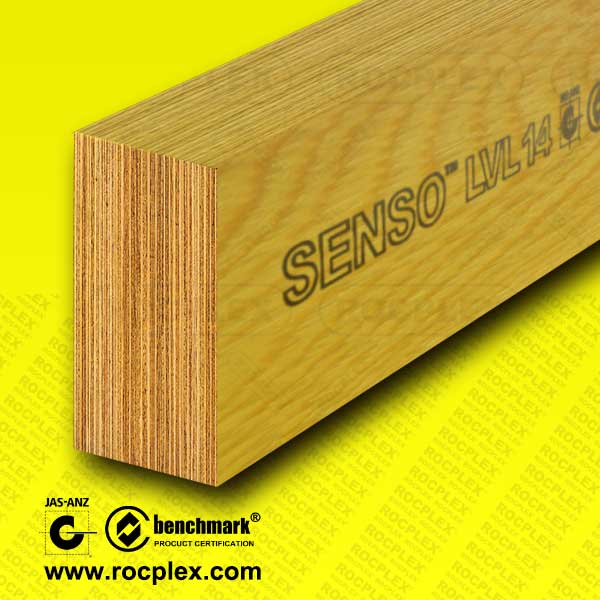

ROCPLEX plastic plywood for strong, stable, concrete formwork

|

1 |

Face and Back |

0.8mm plastic double side |

|

2 |

Grade |

AA garde |

|

3 |

Core Materials |

Poplar core / Combi core / Hardwood core / Pine core / Birch core |

|

4 |

Glue Choose |

MR glue, WBP glue , Phenolic glue |

|

5 |

Thickness |

4-28mm(normal thickness:12mm, 15mm, 18mm, 21mm) |

|

6 |

Specification |

1220mmX2440mm,1250mmX2500mm,915mmX1830mm ,610mmX2440mm |

|

7 |

Moisture Content |

8-14% |

|

8 |

Density |

530-780 kg/ m3 |

|

9 |

Cycle Life |

More than 50 times |

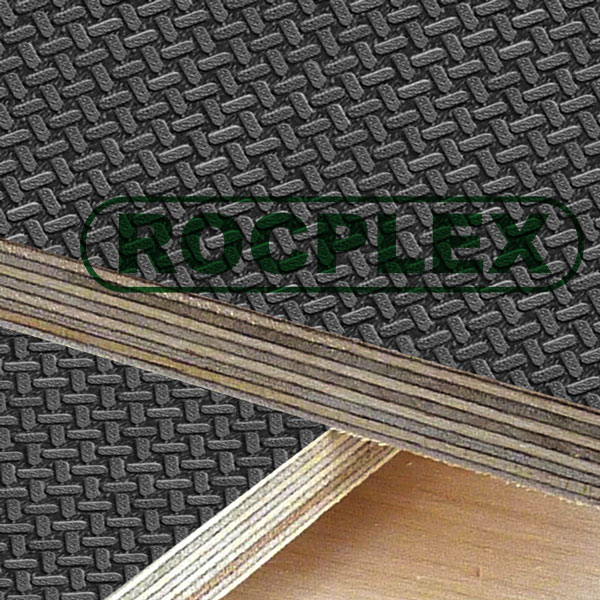

If put in boiling water for 72 hours, it is still glue-sticking and non-deformed.

Physical mood is better than iron moulds and can satisfy the requirements of constructing mould,the iron ones are easy to be deformed and can hardly recover its smoothness even after repairing.

If used abide by the illustrations strictly, it can be reused more than 50 times.

Reducing the cost greatly and avoiding the disadvantages from ( rustily and erosive of iron mould).

Solves the problems of leaking and rough surface during constructing process.

Particularly suitable for watering concrete project ,can make the concrete surface smoonth and flat.

|

ROCPLEX Plastic plywood Save cost |

||

|

Be special for phenolic glue and film |

The film faced plywood can be disassembled and used repeatedly for both faces,saving 25% of the cost. |

|

|

Optimization for the special grade of core |

||

|

Be special for adhesive |

||

|

ROCPLEX Plastic plywood Shorten duration |

||

|

Excellent effect of demoulding |

Shorten 30% of the duration. |

|

|

Avoid the reconstruction of the wall |

||

|

Be easy to incise and blend |

||

|

ROCPLEX Plastic plywood the high quality of casting |

||

|

The flat and smooth faces |

The faces are flat and smooth, avoiding bleeding out remains of bubbles and concrete. |

|

|

The structure of waterproof and breathability |

||

|

The edges are polished carefully |

||

|

Container Type |

Pallets |

Volume |

Gross Weight |

Net Weight |

|

20 GP |

8 pallets |

22 CBM |

13000KGS |

12500KGS |

|

40 HQ |

18 pallets |

53 CBM |

27500KGS |

28000KGS |

|

|

|

Product detail pictures:

Related Product Guide:

Questions and answers encountered in the use of plywood plates

ROCPLEX matine plywood

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Professional China Shuttering In Building Construction - Plastic Plywood – ROC , The product will supply to all over the world, such as: Rio de Janeiro, Bangkok, Colombia, Our company has already had a lot of top factories and qualified technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, skilled operation is our work, service is our goal, and customers' satisfaction is our future!

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!